So I bring to your attention a simple, but very long recipe for cooking ...

In the modern variety of services on the market building materials, it is easy to find help in sharpening cutters.

But don't rush this work you can do it yourself. This is typical not only for work on sharpening cutters, but also for other types of work.

The standard milling machine has two chucks of different configurations. One of them for three spade cutters, and the second for two and four spade cutters. err in this case difficult, because if the number of cutter feathers is not set correctly, it will not be possible to insert the cutter into the chuck.

Having decided on the choice of cartridge, you can proceed to the direct stages of sharpening cutters:

One of the appropriate cup sockets must be used. From standard set collets we select the corresponding collet in size (8 mm, 10 mm, 12 mm).

We put the collet into the chuck and fix it with a clamping nut. This procedure is done without any effort, the clamping nut rotates freely and does not need to be tightened.

To sharpen the cutter on the end, you must use the second socket for the cartridge located on the machine.

In this case, you need to do the steps described earlier to set the diameter and length.

This procedure can be performed by yourself and use improvised means.

Such an opportunity will save money, and in case of repeated use, it will save valuable time.

The quality of manual sharpening is significantly different from sharpening using a special machine, but the manual version saves time.

A milling cutter is a tool used to process various products. Milling cutters of various types are used, which allow you to change the external and internal surfaces with the required accuracy. To achieve high productivity, the cutter must have a high condition - be sharply sharpened. Sharpening end, wood, plastic, glass is carried out using special machines and equipment.

Sharpening is carried out to restore cutting ability, with operations performed contour-wise and separately.

Cutters received for sharpening are usually pre-grinded on a cylindrical surface using a circular grinder to eliminate damage with further sharpening of the back or front of the teeth.

End mills with a pointed tooth shape are sharpened along the back surface with a special disc-shaped or cup-shaped circle. To do this, the circle is installed with respect to the axis at an angle of 89 °, which makes it possible to achieve the required contact between the contacting surfaces.

When sharpening the back surfaces of end mills, 2 main methods are used:

When using the multi-element method, the cutting edges are sharpened separately. First, the main surfaces of all teeth are sharpened, then auxiliary and transitional.

With the contour method - sharpening is performed sequentially for each tooth in one operation. A single-turn sharpening method is also used, when the cutting edges are processed in one operation. All teeth are sharpened in one revolution, the allowance is removed using a grinding operation.

On the industrial enterprises apply different types tool:

For processing blanks, equipment is used that is designed for work:

Milling cutters with appropriate equipment are usually produced as sets with mounting dimensions of the mounting part of different diameters. In order for the cutter to be used a long period it must always be sharpened, and during the working operation it is necessary temperature regime, which does not allow overheating, which reduces their strength characteristics.

When processing workpieces, worm cutters are most often used.

Characteristics of worm cutters are strictly regulated by GOST 9324-60 and are produced:

Prefabricated hobs (for modules from 10 to 16) are used with insert dies, which are made of high-speed cast steel or forged.

Hobs (for modules 18 to 30) are made by welding and setting carbon steel teeth on the base.

When using worm cutters for cutting cylindrical gears, the working parts of the tooth wear out unevenly.

To increase the period of use of worm cutters, a method of height correction is proposed by changing the shape of the spatial curve characterizing the workflow. The method of axial displacement of the tool is also used, which increases the speed of operations with an increase in the life of the worm cutters.

The process of sharpening hobs is carried out along the front part, and sharpened along the back surface of the tooth. After the end of the sharpening process, measurements are taken:

The equipment used to mount the tool is divided into 2 types:

The end equipment is attached with a collet and a chuck, and the nozzle equipment is used by mounting it on the spindle using a special mandrel.

For fixing the tool, mandrels of 2 types are produced:

Center bars are produced with a tapered shank, which has dimensions corresponding to the hole in the spindle, and is produced in 2 types 7:24 and Morse taper.

Allowed when using of this type mandrels to install several cutting tools with fixation with special rings.

When using a cylindrical end mill, a collet chuck is required. Usually the equipment includes 7-11 collets allowing you to pick up required size for secure fixation.

To carry out the milling process, it is necessary to fix the workpiece, for which they are used:

Rotary round tables are used for milling workpieces with a curved surface.

This type of tables has a wide range of offsets:

Clamps or clamps allow you to fix products with the help of special elements, which in turn are attached to the table with bolts and nuts. For fixing small-sized workpieces, a vice is used, simple and with a rotary mechanism.

For fixing parts with cylindrical shape they use a three-jaw chuck and special centers that, with the help of clamps and lunettes, carry out fixation, as well as the use of dividing heads. These fixtures are used to process parts at a given angle during rotation.

The dividing head consists of the elements:

A three-jaw chuck is attached to the spindle, designed to fix the workpiece, the other end, which rests against the headstock. The block can rotate with fixation at the required angle. When processing a long workpiece, steady rests are used for fixing.

All photos from the article

Now manufacturers produce many types and sizes of cutters designed for processing different materials, including wood. You can sharpen a blunt fixture with your own hands on a universal or special machine as well as manually.

For the production of cutters are used different materials. Tool steels are suitable for wood: high-speed, alloy and carbon. For the processing of metal, plastic, ceramics, stone-like materials, hard alloys, diamonds, elbor, and mineral ceramics are used.

Note!

If the cutter has soldered teeth, this does not always mean that they are made of carbide.

It can also be high speed steel.

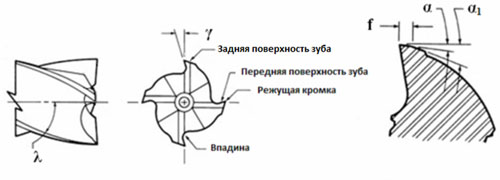

By design, the cutters of the cutters are divided into sharp-sharpened (pointed) and backed.

Each tooth is a separate incisor.

It has standard parameters: rear (a) and front (y) angles, sharpened surface area (n), slope angle (l).

The value of the angle depends on the type of cutter, the brand of its material and the type of workpiece being processed. When cutting wood, the main front angle of sharpening is selected in the range of 10-20 degrees, sometimes more. The back angle also fluctuates in a wide range of values.

End shaped tools for wood can be sharpened by hand using a thin diamond stone. The cost of performing this operation by a specialist is also low.

Note!

When the fixture has a removable guide bearing, it must be removed before sharpening.

In an attempt to save time, you can ruin it and the entire cutter.

By changing the position of the copier needle so that its end touches different points of the tooth groove (for example, center, edge), you can change the values of the rear angles a and a1.

Now about sharpening end cutters.

Sharpening is a rather complicated operation. Refers to the process should be extremely careful. After all, the further efficiency of work with wooden blanks. The video in this article will continue to acquaint you with the nuances of sharpening.

Domestic and foreign manufacturers produce hundreds of types and thousands of standard sizes of all kinds of milling cutters, which are classified according to technological features and design features.

Sharpening is carried out on specialized and universal machines for sharpening cutters, less often manually.

From tool steels, grades U7A, U8A, U9A, KhG, KhV5, 9KhS, KhVG, etc. are used.

High-speed tool steel, used for the manufacture of cutters, is divided into steel of normal productivity (P6M5, P9, P12, P18, etc.) and increased. The latter category includes steel alloyed with cobalt, vanadium, tungsten and molybdenum (R6M3, R18F2K5, R9F2K10, R9F2K5, etc.).

The carbides used to make cutter teeth are produced in the form of plates. standard sizes and forms attached to the cutter body by high-temperature soldering (for example, PSR-40 silver solder) or using threaded connections (prefabricated cutters). They consist of tungsten, titanium and tantalum carbides bonded with cobalt. Cutters made of tungsten-cobalt alloys (VK2, VK3, VK6, VK6M, VK8, etc.) are used for processing cast iron, non-ferrous metals, and non-metallic materials. Titanium-tungsten-cobalt alloys (T5K10, T15K6, T14K8, T30K4, etc.) are less strong than alloys of the VK type, but they have higher wear resistance when machining parts made of various kinds become. Three-carbide alloys, consisting of tungsten, tantalum, titanium and cobalt carbides (TT7K12, etc.), are also mainly used for steel processing.

If the cutter has soldered platinum cutters, this does not mean that they are made of hard alloy. They, for example, can be made of high speed steel.

According to the design of the teeth, cutters with pointed (sharp-sharpened) and backed teeth are distinguished. For pointed teeth, the part of the rear surface of width f, adjacent to the cutting edge, is a plane. Pointed teeth are sharpened on the back surface. Although, if necessary, they can be sharpened along the front surface of the tooth.

The geometry of the teeth of the cutter: a - sharpened tooth, b - backed tooth

At the backed teeth, which are equipped with shaped cutters, the back surface is made along the Archimedean spiral. Since the processing of the shaped surface is very difficult technologically, the sharpening of milling cutters with backed teeth is carried out along the front surface.

Regardless of how many teeth there are on the cutter, each of them can be considered as a separate cutter, characterized by parameters that are standard for any cutter - front (γ) and back (α) angles, the size of the ground to be ground (f), the angle of inclination of the teeth (λ) .

Site f represents the part of the back surface of the tooth, which is subjected to grinding when sharpening along the back surface. On this surface, the main wear of the teeth occurs, its size affects the magnitude of the friction force between the cutter and the workpiece, so it must be maintained within a certain range.

Main rake angle γ- the angle between the tangent to the front surface and the axial plane. It is measured in a plane that passes through this point perpendicular to the main cutting edge.

Relief angle α- the angle between the tangent to the back surface at the considered point of the main cutting edge and the tangent to the circle of rotation of this point. The function of the angle α is to reduce the friction between the cutter and the workpiece.

Auxiliary relief angle α 1 characterizes the increased clearance between the treated surface and the body of the tooth. The need for sharpening the cutters along the auxiliary angle arises at a certain amount of wear of the cutter and an increase in the area f. Its purpose is to reduce friction between the tooth and the workpiece. Not all cutters have this angle.

Depending on the shape and direction of the cutting edge, the teeth can be straight or helical. The inclination of the teeth of the cutter is characterized by angle λ between the developed helical edge and the axis of the cutter.

The angle values depend on the type of cutter, grade of alloy or steel from which it is made, and the type of material for which it is intended.

When processing viscous materials, the main rake angle is selected in the range of 10-20° or more. For carbide cutters for steel machining, it is close to zero or even negative. The back angle can also vary widely.

Shaped end mills can be sharpened without a special tool for sharpening cutters, along the front surface, with a thin diamond stone. The bar either lies on the edge of the table, or, if the cutter has a deep recess, it is fixed as shown in the photo below. The cutter is driven along a fixed bar.

During the sharpening process, the bar is wetted with clean or soapy water. After sharpening, it is washed and dried.

As the front surface is ground down, the edge will sharpen, and the diameter of the cutter will decrease slightly.

If the cutter has a guide bearing, it must first be removed (if possible) and only then sharpened. An attempt to save a minute will end with a ruined bearing and a damaged cutter. You also need to clean the cutter from the remnants of wood resin using a solvent.

As when sharpening any other tool, you need to use whetstones of different grain sizes, depending on the thickness of the material to be removed and the required surface cleanliness. Before sharpening, you need to make sure that the bar has the correct shape.

When sharpening each cutter, to maintain symmetry, you need to try to make the same number of sharpening movements and with the same pressure.

If the material of the cutter's cutters is soft enough, instead of a bar, you can use abrasive paper glued to a flat surface (a hardwood lath or a strip of steel).

End mills for wood can also be sharpened on a grinder with a low wheel speed using an appropriate abrasive wheel.

When using abrasive wheels (especially diamond wheels), it is desirable to cool them with coolant.

One of the significant disadvantages of diamond is the relatively low temperature stability - at a temperature of about 900°C, the diamond burns out.

With increasing temperature, the microhardness of abrasive materials decreases. Increasing the temperature to 1000°C reduces the microhardness by almost 2-2.5 times compared to the microhardness at room temperature. An increase in temperature to 1300°C causes a decrease in the hardness of abrasive materials by almost 4-6 times.

The use of water for cooling can lead to rust on machine parts and assemblies. To eliminate corrosion, soap and certain electrolytes (sodium carbonate, soda ash, trisodium phosphate, sodium nitrite, sodium silicate, etc.), which form protective films. In normal grinding, soap and soda solutions are most often used, and in fine grinding, low-concentration emulsions are used.

To increase the productivity of grinding with abrasive wheels and reduce specific wear, you should choose the largest grit that provides the required class of surface finish of the tool being sharpened.

To select the grit size of the abrasive, in accordance with the stage of sharpening, you can use the table in the article about sharpening bars.

The circumferential speed of the circle when sharpening carbide teeth should be about 10-18 m / s. This means that when using a wheel with a diameter of 125 mm, the engine speed should be about 1500-2700 rpm. Sharpening of more brittle alloys is carried out at a lower speed from this range. When sharpening carbide tools, the use of hard modes leads to the formation increased voltage and cracks, and sometimes to chipping of the cutting edges, while increasing wheel wear.

The shape of the circle for sharpening the rear corner of the teeth on a cylindrical surface is cup (CC or CHK) or dish-shaped (1T, 2T, 3T), the front angle is dish-shaped or flat.

The essence of sharpening the end mill is that when it moves longitudinally relative to the circle, it simultaneously rotates around its axis in a synchronized manner. Due to this, the edge to be sharpened is always in contact with the wheel at the same height (the same sharpening angle is provided). Synchronization of translational and rotational movements achieved with the help of a copier needle resting against a cavity on the front surface of the tooth. By pressing the tooth to be sharpened to the needle and smoothly shifting the cutter in the axial direction, the operator sharpens the tooth for its entire length in one motion.

Sharpening side teeth. In a simplified form, the sharpening of helical teeth looks like this. The cutter is installed in the collet.

The copier needle is set to a position where it is in its highest position and its tip touches the outer edge of the end mill groove.

The cutter is set to its original (extended) position, in which the needle is located near the shank, resting against the groove of the tooth.

The grinding wheel is moved with the side shift knob to a position where its outer edge coincides with the needle.

The motor is turned on, and the straight feed handle is slowly brought to the cutter until sparking begins. After that, using the feed scale, the thickness of the removed metal is set (usually 25-50 microns).

Sharpening a tooth to its full length is done by retracting the spindle with the cutter until the latter comes off the needle. In this case, you need to ensure that the cutter is constantly in contact with the needle. This ensures the rotation of the cutter, which is necessary for the edge to be sharpened to be in contact with the circle at the same relative position.

To ensure the cleanliness of processing, the cutter pass is repeated one more time without changing the thickness of the metal being removed. This completes the processing of one tooth, and a similar operation is repeated for all other teeth. In order for all teeth to be sharpened the same, do not change the thickness of the metal to be removed, which was initially set using the direct feed handle.

By changing the position of the needle in such a way that its tip rests against different points on the groove of the tooth (on the edge or in the middle, for example), it is possible to change the values of the angle α and α 1 .

End teeth sharpening. To sharpen end teeth, the end mill must be set in a position in which the tooth to be sharpened would be located strictly horizontally. The E-90 sharpening system is equipped with a graduated ring that makes it easy and simple to set the face teeth horizontally. If a cutter sharpening machine is used that is not equipped with a similar mechanism, you can set the horizontalness of the teeth using a square.

Sharpening a horizontally set tooth is done by moving the edge of the grinding wheel along the edge of the tooth. The angle of sharpening is adjusted by shifting the circle vertically or by tilting the spindle with the cutter (if possible).

Permissible deviations of the front and back angle of sharpening of all cutters is ± 1 °. Angles can be measured with a special goniometer 2URI or a pendulum goniometer.

For standard cutters, the radial runout of two adjacent (σcm) and two opposite (σpr) teeth, as well as the end runout, is regulated. Permissible values of radial and end runout of the cutter teeth are given in the table below (for cutters without end teeth, the allowable runout of the supporting ends is indicated).

The quality of sharpening or finishing is checked by external inspection with a magnifying glass. The cutting edges of the milling cutters must be free of burrs and gouges.

If there are notches on the surface of the tooth, then the protrusions will crumble during the operation of the cutter, and it will become dull very quickly. It is necessary to strive to ensure that the surface of the tooth is very smooth.

The presence of cracks on the hard alloy plates is determined using a magnifying glass, wetting the plates with kerosene. In this case, if there are cracks, kerosene comes out.

Video:

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Cutter sharpening operations maintain the technical and physical characteristics of the parts, thereby extending their working life. There are many approaches to the implementation of such activities, the choice among which is determined by the nature of operation and the design of the element. The intensity of cutter wear largely depends on its design, based on which the master selects maintenance modes.

For example, the selection of a method for regrinding high-speed parts is guided by the wear of the front surface. On the other hand, sharpening cutters on the back surface is more suitable for shaped elements. Therefore, it is important to take into account as many operational factors as possible, which will allow you to make the right choice of processing technology.

Such elements are widely used in the processing of parts on copying, molding and tenoning, milling and other machines. As a rule, this is woodworking equipment, although there are also parts for working with metal blanks. Cutters differ in size, shape and purpose.

In general, two categories of elements are distinguished - end and mounted. The former are distinguished by the presence of a shank, which is fixed in a special niche of the spindle. Products of the second group have a central hole, which allows them to be mounted on the working spindle and securely fixed. Accordingly, such sharpening of cutters differs more high level quality, not to mention the ease of handling parts for the operator. Attached elements can be composite, solid and prefabricated.

A feature of this group is the possibility of forming cutting tool from several milling parts. It is also worth noting the category of end mills, which can be prefabricated and solid. The elements are also divided according to the quality of the backed processing. So, sharpening of cutters with relief surfaces is carried out along the front edge in order to maintain the basic angular indicators.

Despite the use of high-strength alloys in the manufacture of cutters, long time operation leads to erasure, as well as deformation of the faces. Over time, worn elements are disposed of, but before the expiration of the working life, the master can restore the characteristics of the part using measures Maintenance. It is important to bear in mind that sharpening cutters allows not only to endow them with the same geometry, providing quality work. This procedure also increases the life of the element, reducing tool consumption. But this does not mean that any cutter can be restored in this way.

Technologists do not recommend bringing the tool to a state of complete wear. Manufacturers of cutters indicate in the markings technical and operational values that are limiting for a particular element, and after overcoming them, the cutting edges cannot be restored.

To perform sharpening, special milling machines, equipped with spindles with an average speed of up to 24,000 rpm. Before starting work on them, the master balances the cutters. It can be done in two ways - dynamic and static. In the first case, the procedure is performed on a special machine, which not only balances the force, but also the moment acting on the cutter during rotation. This technique is especially relevant for cases when the cutter is sharpened for metal.

Machine tools for balancing according to the static method involve only balancing the force acting on the cutter. The element is fixed in the frame, after which it is balanced through a device consisting of two horizontal guide knives. Directly sharpening is carried out on special high-precision equipment.

Machines are produced in different configurations, involving both manual and automatic control. Common to all units of this type is the presence of a working surface on the guides. This design solution makes it possible to achieve high accuracy in moving the element, as a rule, with an error of 0.005 mm.

To ensure high-quality sharpening of cutters, you should not only use the equipment suitable for this task, but also properly prepare it. First of all, the equipment spindles must have sufficient vibration resistance, rotate freely and have minimal runout. Further, the feed mechanism must work stably in all directions provided for by the design without delays and with minimal gaps. Great importance have elevation angle settings - this parameter should also contain high accuracy. For example, sharpening worm cutter, which is performed on automatic machines, involves setting both a certain angle of elevation and a helical groove pitch. If they are used grinding wheels, it is important to ensure a secure fit of the interchangeable washers and spindles, due to which the working element is precisely fitted.

The processing of end elements is most often done manually on universal grinding equipment. Typically, this technique is used to update the performance of a helical tool. In many ways, sharpening end mills is similar to updating cylindrical cutters with a cup wheel. This applies to operations that require the end mill to be centered. seat. Also, similar sharpening is performed on semi-automatic models. In this case, end mills with a diameter of 14 to 50 mm can be serviced. In this case, the processing is suitable for both the back and the front surface.

Milling cutters made of as well as some elements equipped with carbide plates are sharpened in assembled form. The main back surface of the face mill is sharpened with a grinding cup wheel. Before performing the same operation on the plane of the secondary rear side, the element is first installed so that its cutting edge is in horizontal position. After that, the axis of the cutter rotates horizontally and at the same time tilts in a vertical plane. In contrast to the scheme, according to which end mills are sharpened, in this case, the position of the workpiece is changed several times. Work with the front surface of the tooth can be carried out by the end part of the grinding disc wheel or by the disk wheel from the peripheral side.

On the rear main surface, the processing of disk elements is carried out by a cup circle. The auxiliary rear surface is made by analogy with end mills, that is, by turning the cutting edges horizontally. At the same time, the features of processing the end teeth of such a tool are noted. In this case, the grinding of disk cutters is carried out along the front surface so that the processed teeth are directed upwards. The cutter itself at this moment should occupy a vertical position. The angle of inclination of the element axis along the vertical must correspond to the position of the main cutting edge.

End fittings are sharpened without special devices, usually with a thin diamond bar. This element either lies on the edge of the desktop, or, if the cutter has a deep recess, it is fixed additional tool. The cutter is inserted along a fixed bar. During processing, the bar is periodically wetted with water. When the procedure is completed, the master thoroughly washes and dries the product. As the front surfaces are ground down, the edge becomes sharper, but the diameter of the tool will decrease. If the cutter has a guide bearing, it must be removed first and then the operation can be continued. The fact is that sharpening a cutter on a tree along with a ruined bearing can lead to damage to the element. It is also necessary to clean the tool from the remnants of wood resins with a special solvent.

Such elements are less common and at the same time require less effort in the preparation process. Processing is done using grinding wheels suitable grit. In this case, the materials can be different, in particular, the use of parts made of ordinary or white electrocorundum is also common. If you plan to sharpen end mills for metal, made from tool steel, then it is recommended to choose electrocorundum discs. For products with higher characteristics, it is desirable to use CBN wheels. The most productive and efficient sharpening parts are made of silicon carbide. They are used to service cutters made of hard alloys. Before work, the abrasive is cooled, as high temperature loads during the operation can adversely affect the structure of the circle.

Relief elements are used in cases where it is required to increase the stability of the cutting part and reduce surface roughness. The teeth of a relief cutter are processed along the front surface in such a way that after regrinding in a radial section, the profile of the functional edge retains its original parameters until the part is fully exploited. Sharpening of such cutters is also carried out in compliance with a strictly established rake angle. In the case of processing sharp-edged elements, it is necessary to maintain a constant pointing angle.

In essence, this is an operation designed to correct the result obtained during the main sharpening process. As a rule, finishing is performed in order to ensure optimal roughness or in cases where it is necessary to correct the sharpening angle of the cutter with working edges. The techniques of abrasive and diamond finishing are quite common. In the first case, the use of fine-grained silicon carbide wheels is assumed, and in the second case, diamond discs on a bakelite bond are supposed to be used. Both techniques make it possible to handle, among other things, carbide tools.

During the verification process, the master evaluates the geometric parameters of the cutting surfaces for compliance technical requirements. In particular, the runout of the cutter is determined, as well as the degree of roughness of the finished or sharpened planes. Auxiliary devices can be used in the control of parameters directly at the workplace. For example, if the end mill was sharpened on wood material, then the specialist can measure the angles along the working edges. For this, a goniometer is used, in which the scale is presented in the form of an arc. Special ones are also used to evaluate other parameters, again, most of them are focused on checking the geometric data of the cutter.

The need for machining cutting tools persists even in the age of high technology. The only change in this regard has been with the milling equipment control systems. Appeared automatic devices, allowing to optimize the process of handling blanks. However, milling cutters, bits and other processing metal elements are still performed using abrasives. Of course, there are alternative technologies that allow you to restore the geometry of parts, but so far there is no need to talk about their wide distribution. This applies to laser technologies, hydrodynamic machines, as well as installations that have a thermal effect. At this stage of their development, for economic reasons, many enterprises still prefer traditional methods sharpening.