Individual entrepreneur details in the contract include mandatory and additional information....

When working with tiles, the question arises: what is the best way to cut ceramic tiles? The choice of tool is determined by the scope of work and the properties of the tile itself. There are several ways to cut ceramic tiles.

In any case, special tools will be needed for the work. The simplest of them is a glass cutter; manual tile cutter, for professionals it is recommended to opt for electric tile cutters. With the acquisition of a certain skill, the tile can be cut with a grinder, and a diamond string is used to make art products.

This is the most simple and inexpensive device for cutting ceramic tiles. It has a different design:

The cutting elements of the glass cutter can be replaced as the edge is ground down. How to cut ceramic tiles with a glass cutter? On the front side, a cut line is drawn with a pencil or marker. Keeping the ruler on the line, hold the glass cutter in the direction from the far edge of the tile towards you. The goal is to draw a uniform recess that reduces the strength of the tile web.

Important ! Spend on ceramic tiles once! Otherwise, the incision will be uneven and the tile will break unevenly.

Then lay the tile on the edge of the table or other flat surface. The cut line should line up with the edge. Holding the edge of the tile on the table with one hand, the other gently presses on the edge, which is on weight. The tile should break along the notch. Its edges are polished with a file for ceramic products.

With its help, cut off a strong floor tiles and porcelain tiles up to 15 mm thick. By design, it is a base, carriage skids with a cutting wheel are fixed on it. It is somewhat larger in diameter than in a glass cutter, which makes it possible to achieve a greater depth of cut. The minimum size of the wheel is 1.5 cm. It is also removable and can be replaced after a cycle of work.

Important ! When choosing a model, pay attention to the sliding mechanism of the carriage. It is better if it is made on bearings or self-lubricating o-rings.

At the base of the manual tile cutter is a strip of solid material, with the help of which, after the incision, the tile is broken. There is a T-shaped part in front of the roller on the carriage, which exerts pressure on the two halves of the tile.

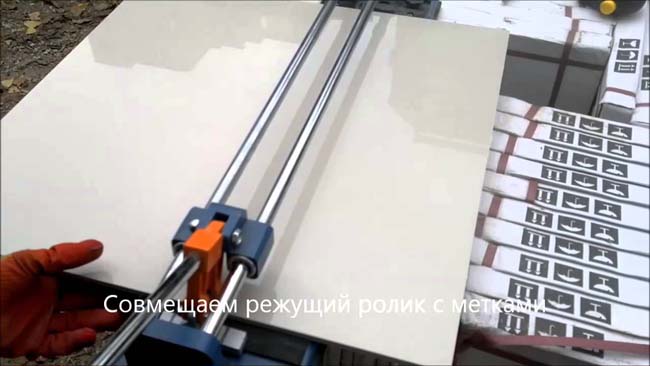

The tile is placed on the base of the tool, having previously marked the fracture line, tightly clamped. The clamping corners must be metal in order to cut floor tiles; enough plastic for the wall. They pull the handle of the carriage towards themselves, making an incision on the front surface of the tile.

The incision is made once. After the end of the incision, press the handle and the tile breaks. The edges will also have to be processed if they fall on the corner. If grout is applied, it will hide all defects.

This tool belongs to the professional category and is quite expensive. With its help, a significant amount of work is easily performed, it cuts any tile quickly, accurately and beautifully. Allows you to make a cut with a width of less than 5 mm, make saw cuts at an angle of 45 degrees, recesses and holes. It is applied for curly cutting. The cut has smooth and slightly rounded edges. In some models, the edge of the disc is immersed in water, in others, the surface at the cutting point is only wetted. During operation, all the dust settles in the cooling tank with water.

It is similar in design to a circular saw. It consists of a platform, a cutting disc fixed on it and an electric motor.

How to cut ceramic tiles with an electric tile cutter.

Attention ! When working on an electric tile cutter, you must use safety glasses, gloves and follow all safety rules for handling cutting edges.

It is necessary to monitor the condition of the cutting edge of the disc, replace it in time. Usually diamond wheels are used. Also regularly, as it gets dirty, change the water in the bath.

Use new wheels for dry cutting, diamond-coated or for concrete work. Bulgarian is better to use with adjustable speed. At a rotation speed above 3.5 thousand rpm, the tile cracks, and the dust content increases significantly.

A warning ! This is a very dusty and dirty cutting process, so don't do it in a clean room.

Cutting tiles is a simple task at first glance, but when you start it, you begin to be surprised: the cutter goes the wrong way, the tile breaks along the wrong line, etc. To avoid unnecessary damage to materials, it is better to first study all types of tools and choose the most suitable one for yourself. convenient option.

A glass cutter is the simplest tool for cutting tiles; a person with no experience will most likely master working with it. Most do not even need to purchase it specifically, as it is already included in the set of home tools. If not, then it does not matter - the glass cutter is quite inexpensive. Outwardly, it resembles a fountain pen with a diamond "pen".

For a small amount of work at home, it makes no sense to buy special tools; you can work with a glass cutter. Additionally, you will need a marker to mark the cut lines. The tile must be laid face up on a flat surface, draw a line, then draw a glass cutter along it. The next step is to place a nail or a metal knitting needle under this line on the back of the tile and press evenly along the marked line from the front side.

But the glass cutter is convenient for cutting tiles in a straight line. Increasingly, this work is not limited even at home. And if you need to cut a corner in a tile cell, you will have to use at least manual jigsaw. Then one side should be sawn off, and the other should be processed with a glass cutter, as described above. True, working with a jigsaw in this case is very tiring, but if we are talking about two or three tiles, then you can be patient so as not to buy more expensive tools.

If you have never worked with a glass cutter before, then take 2-3 tiles for training, you can use it. This will be enough to gain some experience in cutting tiles.

Wire cutters - handy tool for cutting along broken lines. For example, if you need to cut an opening in a tile for water pipe. Here, a glass cutter will also come in handy to draw a broken line on the front side (over the marker). If you cut the curve in this sequence, then the cut line will be neat, without notches and without the risk of breaking the tile in the wrong place.

Most likely, you won't be able to get by with some nippers. When working with them, you need to pinch off the tile in small pieces so that the cut is neat. But “pinching” each tile along the intended line is inconvenient and uneconomical if you need to cut the element lengthwise and in half. Nippers in work are needed more as an auxiliary tool.

If there is a desire to lay tiles in the bathroom or in the kitchen on your own and save on paying for the services of professionals, then due to the rather large amount of work, you cannot do without a tile cutter. electric tool for a single use, it is not cost-effective to buy. You can buy a manual tile cutter, but here you need to consider not too cheap options, otherwise you will have to buy a tile with a large margin. Just keep in mind that such a tool can cope with tiles that are not too thick, no more than 6 mm. So at home, this tool is not suitable for laying tiles on the floor.

Auxiliary devices for working with a tile cutter are the same as in the case of a glass cutter - a marker and a ruler. The tile must be laid so that the drawn line exactly matches the wheel on the mechanical device. The tile is fixed by the “wings” of the tile cutter, which is drawn with a wheel along the intended line once. The direction is set by the handle. After everything is measured and checked, you need to lightly hit the handle, and you get a piece of tile of the right size.

From a hand tool for processing tiles, curiosity is still special machine for cutting. It has a platform for installing tiles and fixing them. Then, with the help of the handle, the cutter is drawn along the intended line and chipped off. For all this, there is a place on the machine, or rather, devices for this succinctly fit on its surface. There is only one inconvenience: most often, machines are made for one type of cut, for example, at 45 degrees. But there are models that are more functional.

With the help, you can process almost any tile easily and in a significant amount. Why "almost"? Because this machine is unlikely to withstand stone tiles, the diamond cutter will be the first to give up. The principle of operation is the same, but the tile must be pressed more tightly against the working surface, since the cutting speed is quite high. The electric machine is equipped with an additional tray for water, which is necessary to cool the disc that heats up during operation. The water in the tank must be changed periodically and make sure that the tile cutter does not overheat during operation. Safety precautions: watch your hands and protect your eyes.

Bulgarian construction work does not use unless lazy. This is an indispensable and multifunctional thing. Unlike an electric tile cutter, the purchase of such a tool, despite the price, is a very practical and useful investment. It will come in handy in many cases. Cutting tiles with a grinder is a pleasure, and it will overcome tiles of any thickness. It can cut lines of any configuration: broken and rounded. Bonus: with a grinder you are mobile, which you cannot boast of electric machine.

Although there are some uncomfortable moments - too noisy and dusty. cut tiles the right sizes grinder is better in advance and in separate room and not in the workplace. Accordingly, measurements and calculations of tiles should also be done on preparatory stage, and mark each cut piece of tile from the wrong side, so as not to look for it when laying and not to confuse anything. From a safety point of view, it is ideal to work as a grinder with an assistant, because holding a tile with one hand and a growling tool with the other is inconvenient and dangerous. In addition, protective goggles and a respirator must be worn during work to protect against small particles dust.

When there is a supply of abrasive files, you can cut curly lines on tiles electric jigsaw and do not suffer with the grinder. It should be noted that they can work exclusively at home, when you need to cut broken lines Literally on 5-10 tiles. With a large volume, the jigsaw, if it can handle it, then it takes enough time for the tool to have time to cool down from overheating. During cutting, the file must be constantly moistened with water. It should be noted that when working with a jigsaw, compared to a grinder, the cuts are more accurate and even. But he can only cope with tiles for walls of medium thickness.

Why do you need a drill when cutting tiles? At the final stage of work, when the tiles are already glued to the wall, you need to cut holes for sockets or switches for hooks for hanging furniture, decor. For such work, a drill is very handy. For holes in the tiles, you need to use a spear-shaped drill. Before starting work, the tile around the area marked with the marker must be pasted over with adhesive tape or electrical tape to avoid accidental cracking.

In conclusion, we will give recommendations that may be useful to novice craftsmen when performing work on cutting tiles. Before starting, sort through all the purchased material. If the package contains a tile with minor defects that were not noticed upon purchase, it can be used by cutting out a bad place. Before cutting, the tiles must be soaked in water for at least 1-2 hours. Wet tiles will be easier to cut, and the dust from it will scatter less.

If rough chips form during cutting, they can be removed by cleaning the tile fragment sandpaper. When there is glaze on the front side, it is better to additionally draw the place of the future chip after marking with a marker with a glass cutter, then the tile will not crack or crumble when cutting with an electric tile cutter or grinder.

It is difficult to cut a narrow strip with a glass cutter. Strips of tiles 5–10 mm wide can be broken off with wire cutters, having previously drawn a line along the glazed surface, as indicated above. When buying a glass cutter for cutting tiles, ask the seller about the oil model. In it, oil is supplied to the roller from an ampoule located in the handle of the tool. The oil glass cutter will slide over the surface of the tile, which will help to avoid unwanted chips.

The need to cut tiles arises in almost every case when tiling surfaces is made. You can deal with this task in different ways. For cutting, there are many devices, both special and improvised, adapted for a particular type of work.

Tile cutter is a popular home appliance

On a production scale, the operation takes a few minutes. We are talking about the method of waterjet cutting of tiles or, in other words, with water with particles of sand or diamond chips, a thin jet of liquid with abrasives is supplied under great pressure.

At home, special tools or other suitable equipment and devices are used.

Please note that cutting floor tiles can be more difficult, as they are thicker and stronger than wall tiles.

Main tools:

Popular Home Tools

Let's consider in detail how to perform various kinds works.

For thin tiles use a glass cutter. First fix the element on a flat surface. Make a mark on the front side and draw a cutter along it. The pressure should be good, and the movement confident. Tap the tile along the groove and press one half of it. You can do a similar job with a nail. For floor tiles better use hand tool due to its strength.

Glass cutter for simple processes

If there is a large amount of work to be done or you are dealing with a durable facing material, there is nothing better than an electric tile cutter or grinder. In the first case, you need to work in the direction of "on yourself", in the second - vice versa.

It will be more difficult to cut the tiles at 45 degrees. The same tools are used here. The electric tile cutter allows you to create a slope due to its design. It will be more difficult to make a corner with a grinder, since you do not have an exact guideline. We'll have to grind the edge "by eye". It is possible to cut 45 degrees and with the help of the simplest devices in combination with further processing file, but it will take a lot of time and besides, it threatens to form chips.

Making a 45 degree angle cut is easiest with an electric tile cutter.

For this use different instruments, but the main one is a drill with special nozzles:

Drill bits

A popular way to cut a large circle in a tile with your own hands combines several methods. First you need something sharp to outline the contours. If you have a crown of the required diameter, use it, but often you have to resort to the help of a grinder. After basting, drill a hole in the center and cut the corner along the radius. Next, you need to work with pliers, breaking off a piece from the incised contour. Notches are further processed with a small file.

To make it easier to drill tiles, use a template made of plywood or glass, in which a circle of the desired diameter has already been made.

To make a hole, use a grinder or pliers

To do such a laborious job with your own hands and without chips, you need to be patient and have tools.

The main device is a jigsaw. With it, you can easily make a cut of any configuration. Due to the thin diamond wire, it is possible to carefully remove the minimum layer of material. At the same time, it is convenient to work according to the template drawn with a marker on the front side of the product.

Curly cut with a jigsaw

To make a semicircle, take the wire cutters. Mark the contours with a sharp nail, glass cutter or file. The disadvantage of this method is the risk of chipping.

If you have to process a large amount of material, it is better to seek the services of special companies that will produce in as soon as possible cutting tiles with a waterjet machine.

Tile work will not do without cutting tiles. It is always necessary to trim individual tiles, but how do you do it?

The article will reveal the main options for how to cut a tile. You will learn what tool is needed for this and how to use it.

All tools for cutting ceramic tiles are divided into two groups: manual and electric.

Hand tools include:

More electrical appliances

In addition to the tool used for repairs, there is special equipment. This includes tile cutting machines.

The choice of cutting tool is determined by many factors:

note

Please note that layout options vary. Diagonal layout will require more pruning.

A mechanical tile cutter will cope with ordinary ceramics. The roller cutter will be the cutting element. It is mounted on a horizontal bar, which is controlled by the tiler while cutting tiles.

The advantages of the method include:

Only one deep cut is made. If you run the wheel over the tile several times, you will get a lot of grooves and you will not get a neat cut.

The tool, which is commonly called the "grinder", is called angle grinder - angular Sander. The angle grinder is suitable for cutting ceramic tiles of different thicknesses, including porcelain stoneware.

To cut the tiles with a grinder, you need a special disc. Watch the video

Use diamond-coated metal wheels: they will last longer than others and provide a smooth cut.

We cut the tile only from the front side to reduce the number of chips and small cracks. Before starting work, prepare workplace. The tile should lie on a flat base, and the circle should have a diamond coating.

If the coating is worn out, cutting off the tile will not work; you will only damage it. Ushm is held vertically, and cut away from you. During operation, do not press hard, otherwise the tile will crack.

Do not forget to ventilate the room so as not to work in dust.

Often used for cutting tiles and drilling holes electric drill with various nozzles. Holes are needed in tiles to hang shelves, hooks, decor elements. Holes of larger diameter are made for sockets, switches, to bypass pipes, etc.

Keep the following in mind when working:

You need to work at low speeds, so the drill must have a speed control function.

The use of a special tile drill, which is commonly referred to as a “feather”, as well as a set of diamond-coated bits will speed up the process.

When working, you need to remember about your own safety. Glasses and gloves will protect against cuts and chips in the eyes. The cut edge of the tile is sharp and dangerous.

First, mark up with a marker. Start at low RPMs, then gradually increase RPMs. Do not press on the tile so that it does not crack.

Jigsaws are either mechanical or electric. We will focus on the consideration of the mechanical model. The tool will provide a smooth cut and safe cutting. Such a jigsaw is made in the form of an arc with a handle. On the arc is a cutting blade - a special string with notches.

How to cut big hole in a tile with an electric jigsaw, see this video

With a mechanical jigsaw, you can carefully make a curly cut. The process is laborious, but the beautiful result is worth the effort. It is reasonable to use the method with small amounts of work and in the absence of another tool for cutting tiles.

Electric jigsaws are equipped with abrasive files that will quickly cut through ceramics and will remain “in service” for a long time.

If you need to bite off a small fragment or trim the cut, use ordinary wire cutters. A simple but problematic way. Don't try to bite off too much.

Mark a circle or draw a line along which you need to bite off the tile. Then carefully remove the excess fragments with wire cutters.

Important. Work with gloves to avoid cutting yourself on the sharp edges of such a cut.

If there is no special tile drill or diamond-coated bits, a concrete drill with a pobedit tip is suitable for drilling a hole. Sharpen it so that the drill is sharp and better through the layer of glaze.

Make sure that the drill is not on the jackhammer function, otherwise you may deform the tile. Work carefully, do not put pressure on the drill, so that the tile does not crack under pressure.

For drilling holes of large diameter, diamond-coated crowns are used, but sometimes they are not at hand. Use conventional drill on tiles.

Draw a circle, and drill smaller holes in this circle. Then, with wire cutters, remove all fragments of the tile.

Professional equipment is not affordable for a modest tiler; it is more often used for industrial purposes or by employees of a large construction organization.

Professional equipment differs in configuration and type of cutting:

laser machine. The cut is performed by a laser beam, which breaks through tiles of any thickness and texture. The advantage of the machine is that it can cope with tiles of any thickness, density and relief, and as a result, an even cut will be obtained without edge melting.

Waterjet cutting method. Most often used for making mosaics. Under high pressure, a jet of water with abrasives exits the nozzle. This pressure is enough to cut through ceramics.

Frazier. The tile router can handle dense and durable materials, even with natural stone. The cut will be even and neat.

For a small repair, such special equipment is not needed, but you need to know about all the possible options.

Outcome

Tile cutting can be done with a tile cutter, grinder, jigsaw and special equipment, such as a laser machine or a milling cutter. Each of the options has its own advantages, so it's up to you to choose.

Depending on the amount of work, financial capabilities and other features, you will choose a tool for cutting tiles.

The history of ceramic tiles goes back thousands of years. AT Ancient Rome it was widely used to decorate the palaces of the nobility, and in Ancient Greece- temples. Ancient masters created huge panels and amazing wall ornaments from multi-colored tiles.

History is silent about what tools were then used to cut tiles, but the fact that they knew how to cut them masterfully is beyond doubt. And since tiles are still made today from the same materials as in ancient times, by firing a specially prepared mixture of clay and sand in a kiln, the methods of cutting tiles that exist today have their roots in ancient times.

Fulfilling Finishing work, it is impossible to do without cutting off some part of the tile to be laid. After all, no matter how hard you try to choose the size of the tile in such a way that it fits exactly, without a trace, on the plane of the wall or floor, mathematical probability such luck is very close to zero.

But even if you are fabulously lucky, then in this case, the presence of gas, water and sewer pipes, as well as exhaust openings, window and doorways will still force you to fit the tile to get around these obstacles.

Therefore, undertaking to lay the tile yourself, be sure to familiarize yourself with the technique of cutting it and purchase the tools and fixtures necessary for this work.

Back to index

Tools that can be used to cut tiles are conventionally divided into two types - professional and adapted. When choosing how to cut tiles, you need to focus primarily on the amount of work performed.

Professional tilers in their work use special tools for cutting tiles. But their work is expensive, and if the volumes are not very large, it is not economically feasible to purchase them. Moreover, it is possible with ordinary tools that anyone can find home master, or which are not so expensive, and therefore it is not so expensive to purchase them.

You can cut tiles with the following tools:

A glass cutter is a hand-held roller tool designed to cut glass. Its roller is made of a very hard alloy capable of leaving on glass deep scratch. You can’t cut thick floor tiles with it, but it copes satisfactorily with thinner wall tiles. But still it is not suitable for performing large volumes of such work.

Manual tile cutter appearance It resembles ordinary tongs, but it works a little differently. In the tile cutter, the tile is fixed with clamps in static state, and then using a special roller, an incision is made in the right place. Such a cut can be made to a greater depth than with a glass cutter. This allows you to cut not only wall tiles, but also thicker floor tiles. When choosing a manual tile cutter in a store, keep in mind that it is better to take a tool with a metal corner rather than a plastic one, since the latter, although much cheaper, does not do a good job of cutting floor tiles.

An electric tile cutter is similar in design to a manual tile cutter, but is a more powerful tool. It easily cuts tiles of any thickness, and is also able to cut thin strips, which is problematic to do with a manual tile cutter, and even more so with a glass cutter. The advantages of an electric tile cutter include the almost complete absence of dust when cutting, as well as the minimum amount of waste.

However, the price of a good electric tile cutter is very high and, with small amounts of work, can exceed the total cost of the rest of the repair. Therefore, it is mainly purchased by construction companies.

A special hacksaw for ceramics looks like a regular hacksaw with a removable stretching blade. However, the very tightly has a special tungsten carbide coating. Working with this tool is characterized by exceptionally even and smooth cuts that do not require additional grinding.

The hole saw is produced in the form of a ring nozzle with teeth, which is mounted on an electric drill. Designed exclusively for cutting round and semicircular holes in tiles for pipes, hoses or taps. The inconvenience of working with a hole saw is that both the tool itself and the tile during cutting are very hot and require periodic cooling, for which they have to be dipped in a container of cold water.

Bulgarian is a well-known universal tool. The grinder cuts not only tiles, but even porcelain stoneware products. It is functional for all cutting operations tiles: cutting off thin strips, cutting grooves and curly cutting edges. But working with a grinder has a significant drawback: when cutting tiles with it, it turns out very a large number of ceramic dust, therefore, the help of a grinder can be resorted to only when all other tools do not do the job or are not suitable for the price.