Hmm, yoda_daro claims that this is a test to determine their sexuality...

We present the third version of the copy-milling machine “Duplicarver-39rdquo;.

Created on the basis of the Duplicarver-29rdquo ; machine, it retained all its capabilities and acquired completely new ones.

Now it has become possible to perform a long volumetric thread.

The maximum diameter of the product is about 30 cm, and the length is not limited, within reasonable limits, of course.

The most typical carving objects can be gun butts, table legs, stair railing balusters, long lamps, tall figurines, and any other object that is sized to fit the working capacity of the machine.

The photo shows a copy of the IZH27M hunting rifle. The product is made of solid alder board. Length 1100 mm.

But if you need to make sculptural carvings, simply remove the long carving kit and get started.

Thus, “Duplicarver-39rdquo; is a universal copier milling machine, perhaps unparalleled in its capabilities, and most importantly - in price.

The machine is equipped with guide tubes 1180 mm. This size, chosen with ease of shipment and transportation in mind, is sufficient for most jobs.

If it is necessary to manufacture longer products, you just need to replace the guide pipes on the machine with longer ones. These are standard aluminum pipes with a diameter of 30x3 mm, which can be freely purchased in any city at a metal depot or in a specialized store.

In the absence of such products in your city, we will deliver you pipes of the required length using a trucking company.

HOW MUCH IS THE DUPLICARVER-3 COST?

To order in Moscow and St. Petersburg, call: +7-911-984-69-18.

We can deliver Duplicarver-3 to any city in Russia. Delivery to Belarus and Kazakhstan is also possible. Read the terms of delivery and payment. and fill out the order form. We will contact you to clarify all the details and issue an invoice.

Sculptural carving:

Very often in our life there is a need to make a copy of an object, so the availability of copying equipment is a modern need for many enterprises. And we are not talking about copy-printing equipment, but about copy-milling machines.

Copy milling machine

They serve to create items that replicate the original sample as much as possible. The equipment makes it possible to produce parts in large quantities, providing high processing speed.

Milling is one of the methods of mechanical processing. The procedure allows for finishing, roughing and semi-finishing of various surfaces of workpieces made of wood, plastic, cast iron, metal (ferrous and non-ferrous).

Milling has a high productivity, which makes it possible to create objects of the required geometric shape.

Milling can be organized in two ways:

Using cutters equipped with modern cutting materials, can carry out processing, replacing the grinding procedure.

Copy-milling machine Duplikarver

A woodworking milling machine, including a mini modification, is used for processing surfaces of planks, levers, covers, cases and brackets of a simple configuration, surfaces of case objects.

Allows you to apply 3D or 4D threads. One of the most popular brands domestic origin - Duplicarver.

Milling machines are found in two categories:

The last group is continuous milling equipment, consoleless, console, longitudinal milling. The first group is copy-milling, key-milling, spline-milling, gear-milling, thread-milling. There are full and mini models.

to the menu

Copy milling woodworking machine is used for copying work on the plane and in volume, for engraving patterns, inscriptions, ornaments, shaped profiles, as well as for simple milling tasks.

Automatic double-sided copy-milling machine Valestrini

Despite the simplicity of the machine, it allows you to create incredibly complex patterns. It can be mini or full size.

The equipment allows you to perform various milling work using carbide and high-speed cutting tools. Can carve. Machines are used in small and large-scale production. Can work in 3D mode with appropriate equipment, CNC. Duplicarver models are very popular.

The machine allows you to create:

The process of duplicating products on a milling machine

The equipment can also be used for:

The Duplicarver wood milling machine allows you to mill curved parts by copying according to a template from which the shape of the future product is copied. Through the use of templates the influence of the so-called human factor is excluded, therefore, the finished products have an identical shape. In many ways, this provides CNC.

Not only a template sample can be used in the work, subsequent products can be made according to the sample of the first one. To increase accuracy, the machine should be supplemented with a copying device called a pantograph.

It can have a different design, but it has an important function - accurate transmission along the profile of the movement of the copying head to the cutting device. Therefore, a high accuracy of the thread is achieved when it is applied.

to the menu

The Duplicarver milling machine uses a cutting carbide tool - a milling cutter. It reproduces the surface or contour of the copier on the product.

Turning and milling machine for wood with copier TFS-1550

This machine master has a hydraulic, mechanical and pneumatic connection with a tracking system responsible for the direction of the cutter. On the one hand, it acts on the amplifying device, on the other hand, it affects the executive body.

The copier is a flat template, contour drawing, reference detail, spatial model. Copier - photocell, finger, roller or probe. Samples can be parts made of wood, plastic or metal. The copier and the workpiece to be processed are placed on a rotating table.

The executive body of the Duplicarver machine is a differential, an electromagnetic clutch, a solenoid, a screw, a spool. In amplifying devices, electro-optical, hydraulic or electromagnetic relays can be used.

The speed of movement of the tracking device determines the accuracy of the profile and the surface roughness of the product. An accuracy of 0.02 mm and a roughness of No. 6 can be achieved. The Duplicarver machine is driven by an electric motor and a power hydraulic cylinder.

The pantograph, which allows you to copy products on a set scale, has a guide pin located on the axis and moving along the copier, as well as a tool spindle and an axis of rotation.

Samples of products made on copy-milling machines

When the finger is moved over the copier, the spindle on the workpiece describes the required geometric shape. The scale is determined by the pantograph by the proportions of the shoulders. Additionally, CNC can be used.

Type of drive:

There are mini and full versions. Such devices can be equipped with CNC.

You can also select more groups of devices that differ in clamping the workpiece and the level of automation:

These can be mini or full size machines.

to the menu

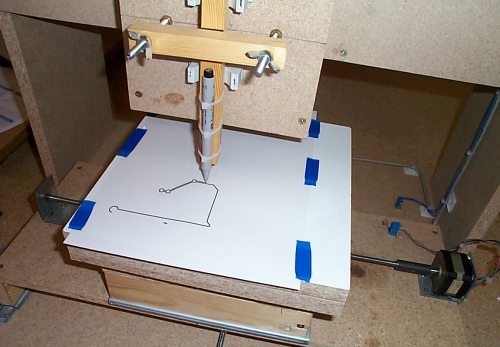

Homemade copy milling machine can be done at home with your own hands. Of course, such mini equipment will not be able to work at the level of industrial designs, but it is quite capable of creating high-quality copies.

Homemade copy-milling machine

A homemade CNC woodworking copy milling machine can be made using a linkage system, an electric motor with a chuck required for a cutter.

A typical design of a do-it-yourself device is:

Desktop copy milling machine for woodcarving with CNC do-it-yourself should be optimized for specific purposes, which must be achieved, for example, for threading. Understanding what parts to be processed, you should perform calculations of dimensions, power, and so on. Then the machine made with your own hands will allow you to implement the necessary tasks.

to the menu

Types and detailed characteristics of milling machines

Milling machines are used in the processing of workpieces and individual parts that have flat or multi-level surfaces. Main purpose

Features of rotary tables for milling machines

This article will discuss the rotary milling tables– devices that significantly increase the efficiency of any manual and CNC milling.

Scope of application of universal milling machines for metal

Universal milling machines for metal are used everywhere for various metal-industrial large-scale work. Their advantage is that they have.

Metal lathe: design features, types, independent.

Among a wide range of various machines designed for metal processing, the universal mini - lathe for metal for the home is also capable.

Copy equipment always comes to the rescue if you need to produce a specific part according to a template within small batches. Copy-milling machines are used both in enterprises that produce products on a large scale, and in small workshops, and in household there is always a job for a wood copying machine. Industrial designs of copiers can produce parts in almost unlimited quantities, but we will focus on models that you can assemble with your own hands and budget machines for small-scale furniture production.

A copy-milling machine is a universal device that is designed to make copies of a wide variety of parts. The machine can work in both two-dimensional and three-dimensional formats. In the first case, copying is made from a template, in the second - from a finished product. The more accurate the machine is made, the more accurate the copy will be, and the accuracy of the machine, as in all means of processing materials, depends on the guides and the rigidity of the power and working structures.

In addition, the copy-milling machine can perform pattern engraving, the manufacture of decorative elements, and sometimes the device can replace the milling machine.

The simplicity of the device, and at the same time the efficiency of copying, made copy-milling machines indispensable in the manufacture of curved and complex parts. Another good property of the machines is independence from the level of professionalism of the operator. The versatility of the machine can be achieved with the help of interchangeable elements, nozzles and copying heads.

The main problem of a milling and copying machine can be inaccuracy, which is associated with vibrations and backlash. A do-it-yourself wood-cutting machine assembled at home is most often prone to such shortcomings. The slightest backlash can affect the quality of the copy, and in order to avoid it, it is necessary to use rigid structures, strong beds, no matter what grade and what thickness the wooden blank is.

That is why such machines, assembled at home, cannot always boast of versatility. With a clearly defined front of work, it is much easier to achieve rigidity and accuracy from the design. The bed of the copy-milling machine should be as heavy as possible in order to dampen the slightest vibrations that can affect the accuracy of the work.

Therefore, the following characteristics must be mandatory for such equipment:

Only such a machine will work fully and accurately.

A CNC machine is a type of copier. Like manual copy-milling machines, they can copy a given part very accurately, and the use of software methods provides many advantages over manual models:

CNC machines are quite complex and functionally rich devices that are fully controlled by automation. In addition, it is possible to integrate the control system of the CNC machine into a computer control system, which will further increase the functionality and speed of the equipment.

Copy-milling machines for wood can have a fairly wide price range, which depends on the level of equipment and the purpose of the machine. The device can be equipped with a variety of systems, both manual control and servo electric system.

In many models of such machines, high-precision sensors are used, which can be electrocontact and inductive. Naturally, the equipment affects the prices of machines. If we take the desktop models that interest us, then the most inexpensive and most popular on the market are YILMAZ, Star, Duplicarver. In the manual version, these models cost about 50 thousand rubles.

Therefore, having well thought out your requirements for the machine, it is quite possible to make such a machine with your own hands according to the drawings or your own design. Several designs that are shown in the photo may lead to the right decision and another useful and uncomplicated machine will appear in your arsenal.

Both in production and at home, it often becomes necessary to manufacture a part whose shape and dimensions are completely identical to the original sample. At enterprises, this problem is solved with the help of such a device as a copy-milling machine, which allows you to make copies of the original part in large series, is characterized by high speed, as well as the quality of the processing performed.

Copy-milling machines and any other equipment of the milling group can be found on almost any industrial enterprise. This is explained by the fact that the milling operation is one of the most common methods used to perform machining. This technology allows you to perform a wide range of roughing, semi-finishing and finishing operations with simple and shaped blanks made of ferrous and non-ferrous metal, work on wood and plastic. On modern milling equipment with high precision and performance, parts of even the most complex shape are processed.

There are two main types of milling: counter (feed and rotation of the tool are in different directions) and associated (the tool rotates in the same direction as the feed). The cutting part of the tools that perform milling is made of various materials, which makes it possible not only to successfully work on wood, but also to process (including grinding) even the most solid metals and alloys, artificial and natural stone.

Milling equipment is divided into two types: general purpose and specialized, to which the copy-milling machine belongs.

The copy machine, belonging to the milling group, is designed for copy-milling work with flat and voluminous parts. In addition, such a device can be used to engrave shaped profiles, apply inscriptions and patterns (even of high complexity) to products, and perform light milling operations on wood and other materials.

An example of the result of a copy-milling machine

Using tools with a cutting part made of various materials, copy-milling machines process parts made of cast iron, different grades of steel and non-ferrous metals. On such devices for the production of parts in small and large series, blades of turbojet engines and steam turbines are successfully produced, propellers for ships, punching and forging dies, impellers for hydraulic turbines, molds for pressing and casting, molds, etc.

On a copy-milling machine, technological operations are performed that are practically inaccessible to universal equipment. The principle of operation of such a machine is based on the copying method, for which a special template is used. The use of a template eliminates the human factor when processing even the most complex parts, so that all finished products have the same shape and geometric dimensions. Conveniently, one template can be used to precisely manufacture a large batch of parts that will be completely identical to each other.

In order to copy the shape and dimensions of the template as accurately as possible, a copier (pantograph for the router) is installed on the copy-milling machine. The purpose of such a device is the exact transmission of all movements of the copy head to the cutting tool.

Copy-milling machines, as mentioned above, are used for planar (profile processing) and three-dimensional (relief processing) milling. As a working tool, cutters are used on them, which, processing the contour or volumetric surface of the part, repeat the movements of the copier. The connection of the working body and the tracking system for manual machines is provided by mechanical, pneumatic or hydraulic elements needed to form the force transmitted from the copier to the working body of the copy-milling machine.

A template on such machines is a flat contour or spatial model, a reference part or contour drawings, and an element that reads the shape and dimensions of the template is a copy finger or roller, a special probe, a photocell. You can use an aluminum sheet or a sheet of other metal, plastic or wood to make a template. The template and the workpiece are located on the rotating desktop of the machine.

Scheme of the moving part of one of the varieties of copy-milling equipment

The working body of copy-milling equipment is driven by such structural elements as a screw, spool valve, solenoid, differential or electromagnetic clutch. Relays installed in amplifying devices of copy-milling machines are electromagnetic, hydraulic or electro-optical.

The quality of the workpiece (surface roughness, shape and size accuracy) depends on such a parameter as the speed of the tracking device. In this case, the following characteristics of the finished product can be achieved: roughness - No. 6, profile accuracy - 0.02 mm. The main elements of the executive circuit of such equipment are an electric motor and a hydraulic cylinder.

Machine at work

The pantograph installed on copy-milling equipment provides copying in a given scale. The design of the pantograph consists of a guide pin, its axis, a tool spindle and a separate axis of rotation. The spindle and the guide pin are located on the same rail, the ratio of the shoulders of which determines the scale of copying.

Moving along the contour of the template, the finger sets in motion the rail, which freely rotates on the axis. Accordingly, on the other side of the rail, the machine spindle makes identical movements, processing the workpiece. On copy-milling machines, which are made by hand, such a device will also not be superfluous, its presence significantly increases the functionality of the equipment.

The equipment of the copy-milling machine may include drives of various types. Based on this parameter, allocate:

Homemade copy machine may refer to any of these types (including copy-grinding machines). You just need to find drawings on the Internet and select components.

An example of a homemade copy-milling machine

According to the degree of automation and the method of fixing the workpiece, the following categories of copy-milling machines are distinguished:

As noted above, on a copy-milling machine, the workpiece is processed using a master device - a copier. All movements of the copier along the contour or surface of the template are transmitted thanks to a special (copier) device to the working head of the machine, in which the cutter is fixed. Thus, the cutting tool exactly repeats all the movements that the copier used to equip the router makes.

Another DIY option

The movements of the elements of the copy-milling machine during the processing of the part are divided into main (rotation and movement of the spindle when the tool plunges into the workpiece material, movement along the contour of the desktop and sled) and auxiliary (movement of the spindle head, sled and table in accelerated mode, as well as installation movements made by the tracer table, copy finger, stops and a clamp that fixes the spindle head).

In aluminum key-cutting machines, two tracking schemes can be implemented: simple action and feedback action. When implementing the direct action scheme, the working body of the machine makes movements due to the fact that it is rigidly connected to the copier. The reverse action scheme does not provide for such a connection, and movements from the copier to the working body are not transmitted directly, but through the tracking system.

As mentioned above, copy-milling machines perform contour and volumetric milling. In contour milling, the movements of the copier occur in a plane parallel or perpendicular to the tool axis. In the first case, the movement of the working table of the equipment can only be longitudinal, and the cutter and copy finger move vertically. In the second case, the table moves both in the longitudinal and transverse directions. With volumetric milling, the part is processed in stages - thanks to several movements of the table and tool, performed in parallel planes.

The direct action scheme can also be implemented through a pantograph, which allows you to reduce the size finished products in relation to the dimensions of the template used (to scale). Most often, such an additional device, which is easy to make yourself, is installed on machines used for engraving and light milling.

Another variation of a self-made machine

Many home craftsmen would like to buy a copy-milling machine to equip their workshop, but the cost of such equipment is quite high. Meanwhile, having a desire, having spent not so much time, effort and financial resources, you can make such equipment with your own hands.

Naturally, home-made copy-milling equipment cannot be compared with professional ones in terms of power, reliability and functionality, but even on such machines you can make high-quality copies, work with wood and process workpieces from other materials. Many people try to fit a copier to an existing milling machine. however, this is impractical, since in this case it is necessary to redo almost the entire machine. As practice shows, it is better to assemble your home-made copy-milling machine from scratch, choosing the appropriate components for this.

The photo below shows an example of a homemade machine with the addition of a video. The creator of the machine is narrating in English, but in principle everything is quite clear and without translation.

Homemade copy-milling device with a pantograph

With your own hands, a copy-milling device is easiest to make according to a typical scheme, which includes a supporting structure - a frame, a desktop and a milling head. The drive for ensuring the rotation of the working tool is an electric motor that transmits movement through a two-stage mechanism that allows you to get two speeds. desktop of this homemade device can be adjusted in height.

Many of those who made a copy-milling machine with their own hands note that when changing operating modes, such equipment begins to show a lot of shortcomings. The most common of these shortcomings are machine frame vibrations, workpiece distortion and deflection, poor copying performance, etc. To avoid such problems, it is best to make the copy-milling device highly specialized and immediately set it up for processing the same type of workpieces. This is explained by the fact that it is almost impossible to take into account all the shortcomings that universal equipment will have when changing operating modes.

Of great importance is the size of a home-made copy-milling machine, which must be selected depending on the size of the workpiece you are going to process on it. When processing large workpieces, significant vibrations occur, which can only be extinguished by equipment that is massive. With this processing, serious loads are transferred to the guide axles of the machine, which must also be able to withstand this.

The first thing you need to do before making a copy-milling machine with your own hands is to decide on the tasks that you are going to solve with it. The size of the desktop, the method of fixing the workpieces and the template, the direction of movement of the cutting tool will depend on this.

Depending on what parts you are going to make on your home-made copy-milling machine (as well as on the material for their manufacture), the power of the electric motor is selected. So, for engraving and other woodworking, an electric motor with a power of 150-200 watts is quite suitable.

The probe and the working body of the machine are rigidly fixed to each other and installed above the desktop so that the height of their location and their planes completely coincide. Such a structure, after installation, must move horizontally and vertically parallel to all sides of the desktop.

In the two videos below, another master talks about making a copy-milling machine with his own hands.

Copy-milling machines for wood are universal units, the purpose of which is to copy products in two- and three-dimensional form. In other words, this equipment can copy flat finished products, and when using special copiers, and three-dimensional models.

Such devices are often used for engraving profiles and various decorative elements. They can also be used for ordinary, not very complex milling work.

With a fairly simple device, such units are capable of reproducing very complex wood products.

Pantograph is essential element machine.

Such equipment is unique, because with its relatively simple design, it is able to copy complex products, even thin handmade.

In fact, the unit was designed for milling curved elements:

Note! The instruction recommends completing it with a special copying device for this. It is called a "pantograph" and serves to accurately report the movement of the copying unit (head) to the main device that processes the part.

When the template has a lot of fine delicate details, the pantograph machine is indispensable.

The photo shows a desktop device with mechanical clamps.

Copy-milling units make it possible to process reliefs or profiles:

Note! The pantograph in the described units plays a crucial role. It is equipped with a special guide "finger".

It moves along the copier, while determining the geometric parameters of the sample with maximum accuracy. The final size of the resulting copy depends on the proportions of the "shoulders" of the pantograph.

The units of this brand are of the highest quality.

The most popular brand of copy-milling machines are Duplicarver brand units:

The executive unit of the device, consisting of an electric motor and a cutter.

Stationary automatic unit.

At the moment, manufacturers produce copy-milling units that differ in many characteristics. Accordingly, the price of equipment is different.

By type of drive, the following machines are produced:

According to the level of functionality and equipment, there are:

The machines also differ in size and degree of automation:

It should be noted that all these devices can be equipped with numerical control (CNC).

Homemade milling and copying machine.

If desired, the copy-milling device can be assembled independently, as they say - at home. The main thing at the same time is to find the correct drawings of the pantograph on wood with your own hands.

What is clear, such a miniature machine will not be able to work on a par with industrial counterparts. However, simple copies wooden products and details it will create.

A home-made unit can be assembled from a system of rods and an electric drive with an installed chuck clamp, which is necessary for a cutter-cutter.

Typical knots homemade device a bit numerical:

Note! The desktop device needs to be optimized for specific tasks. For example, to copy a thread. Having determined which wooden blanks you will have to process, you need to calculate the dimensions, power of the unit, etc.

In the modern world, it often becomes necessary to create a copy of something or reproduce and repeat something. For this purpose, many enterprises widely use copy-milling machines, which are designed to create products, the shape of which is most consistent with a given initial sample. They allow the production of parts in large quantities, while ensuring a high speed of processing and manufacturing of each element.

Milling is one of the common machining methods. With the help of milling, roughing, finishing and semi-finishing of shaped and simple surfaces of workpieces made of steel, non-ferrous metal, cast iron and plastics are carried out. Milling is characterized high level performance, which allows the final result to obtain products of the correct geometric shape.

Milling can be carried out in two ways: up milling procedure (against feed), when the feed is opposite to the direction of rotation of the cutter, and climb milling (by feed), when the directions of rotation of the cutter and feed coincide. Using milling cutters equipped with modern cutting materials (mineral ceramics, synthetic superhard), you can process materials that are hardened to high hardness, thereby replacing the grinding procedure.

Milling machines are designed for milling the surfaces of levers, slats, housings, covers and brackets of a simple configuration, complex configuration of contours (such as templates, cams), surfaces of body parts. Milling machines are divided into two main categories: general purpose machines and specialized machines. The first group includes longitudinal milling machines, console, consoleless and continuous milling. The second category includes thread milling machines, gear milling machines, spline milling machines, keyway milling machines and copy milling machines.

Copy-milling machines are usually used to perform copying work in volume and on a plane, as well as in volume using three-dimensional models and corresponding copiers, for engraving various shaped profiles, patterns, ornaments and inscriptions, as well as for light milling work. The indisputable advantage of such units is that it is capable of performing incredibly complex patterns with its own simple device.

On the machine, you can perform various milling work on steel, cast iron and non-ferrous metals using high-speed and carbide tools in large- and small-scale production. On such machines, ship propellers, blades of turbojet engines and steam turbines, hydraulic turbine impellers, punching and forging dies, press and casting molds, various cams, dies, molds, metal models and blanks are manufactured.

Such equipment is also used for drilling holes for handles, locks, latches, metal hinges, as well as making frames for mirrors and channels of any size on plastic and aluminum profiles, as in the video about copy-milling machines. On the universal machines processing of such products is practically impossible.

The copy-milling machine is intended for milling curved parts by copying according to a template from which the shape of the future product is copied. The use of templates makes it possible to exclude the influence of the human factor during such a complex operation, and all finished parts as a result, they have the same shape.

For the manufacture of several completely identical products, you can not only use a single template, but also make all subsequent parts according to the model of the first one. However, for the most accurate repetition, it is recommended to supplement the machine with a copying device called a pantograph. Its design is different, but the function is the same in all cases - it is more accurate to convey the movement of the copying head along the profile to the cutting device.

The copy-milling machine is designed for processing profiles (planar milling) or reliefs (volumetric milling) of products using a cutting carbide tool - a milling cutter. The cutter reproduces on the product the contour or surface of the setting device - the copier. The master device of a manual copy-milling machine has a pneumatic, mechanical or hydraulic connection with the tracking system, which is responsible for the direction of the cutting tool, acting on the amplifying device on the one hand, and on the other hand, affecting the executive body.

A flat template, a spatial model, a reference part, a contour drawing can act as a copier, and a probe, a copy roller or a finger, a photocell can serve as a copier. Copy samples can be made of metal, plastic or wood. The workpiece and the copier are fixed on a rotating table.

The executive body can be a spool, a screw, a solenoid, an electromagnetic clutch, a differential. In amplifying devices of copy-milling machines, electromagnetic, hydraulic or electro-optical relays are used. The surface roughness of the workpiece and the accuracy of the profile depend on the speed of movement of the follower: roughness No. 6 and a profile accuracy of 0.02 mm are achieved. The actuator circuit is driven by a power hydraulic cylinder and an electric motor.

Copying in the prescribed scale is carried out using a special device called a pantograph. If you are interested in how to make a copy-milling machine yourself at home, then you can supplement it with this device. The pantograph has a structurally guiding finger, which is located on the axis and moves along the copier, the axis of rotation and the tool spindle. When moving along the copier of the finger on the workpiece, the spindle describes a geometrically similar figure. And the scale of copying is determined by the proportions of the pantograph arms.

By the type of drive, the following main types of copy-milling machines are distinguished: with a pantograph, which is designed to work in 2 and 3 dimensions; universal devices with a pantograph, which is located on a swivel sleeve in a vertical plane; single and multi-spindle units with rectangular and round table; with mechanical feed, electric and hydroficated, as well as photocopying.

There are several types of similar milling and copying machines, which differ in the level of automation and clamping of the workpiece:

The processing of products on a copy-milling machine is carried out according to a master device (copier), the action of which causes a corresponding movement of a special cutting tool relative to the workpiece through the copier. Through the copier, the copier acts on the executive bodies, while the workpiece and the cutter recreate in relative motion the surface that is set on the copier.

The main movements are the rotation of the spindle, the movement of the table and sled along the contour, the movement of the spindle head during plunging. Auxiliary movements - acceleration of the movement of the slide, spindle head and table, installation movements on the table of the tracer table, stops, copy finger and clamping of the spindle head.

Aluminum copy-milling machines are able to work on 2 tracking schemes: feedback action and single action. The copy probe and the cutter in the single-action scheme are rigidly connected to each other, and the cutter is transferred to the movement of the probe along the copier. The deviation of the copy probe in a feedback circuit causes a mismatch in the position of the copy probe relative to the cutter.

The result of such a mismatch enters a special tracking system, which gives the actuator a signal to correct the trajectory of the tool. In this case, there is no rigid connection between the cutter and the copier, and the copier does not perceive the cutting force, but only transmits the corresponding signal to the executive bodies.

There are two types of copy milling - volumetric and contour. The copier curve during contour copying can be placed in a plane that is parallel or perpendicular to the axis of the cutter. The table in the first case with the copier and the workpiece moves in the longitudinal direction, the control of the change in the curve is performed due to the vertical movement of the incision and the copier finger. The table with the copier and the workpiece in the second case moves in the transverse and longitudinal directions according to the shape of the curved line of the copier.

The complex spatial surface of the workpiece during volumetric copying is processed by the cutter sequentially, by means of several parallel table moves, that is, contour copying is performed with each working stroke. At the end of the pass, the cutter is displaced relative to the workpiece perpendicular to the line by the value of the transverse feed, then the next working stroke occurs.

There are also direct-acting copy-milling machines in which the probe of the cutter transmits movement through the pantograph. Such machines are mainly used for light engraving and milling work. When using a pantograph, it is possible to carry out, in addition to copying, a reduction in the scale of blanks in relation to the copier. The movement of the copy probe along the copier, which is installed on the machine table, is transmitted to the spindle, which, when processing the workpiece, describes a contour similar to a geometric copier.

Currently, there are milling and copying machines of various designs and levels of complexity on the market. However, it is not always possible to buy one, and the price of a copy-milling machine is quite high. Therefore, we often face the question of how to make a copy-milling machine at home.

Of course, home-made machines cannot fully compete with industrial models, but still they are efficient and allow you to make high-quality copies. I would like to make a reservation right away that it will be very difficult to adapt a copying device to an industrial milling device, and this applies, first of all, to a radical alteration of the entire apparatus. Therefore, it is easiest to assemble a home-made copy-milling machine practically from scratch using a traction system and an electric motor with a chuck for a cutter.

There can be many designs of copy-milling machines. The typical design of the apparatus is as follows: the machine structurally consists of a working table, a supporting frame and a milling head. The working surface can be adjusted in height, the milling head is equipped with an electric drive motor and a two-stage transmission mechanism that provides two speeds for the milling shaft.

Many homeowners complain that when copying a product, the resulting part has many flaws and inconsistencies that appeared when changing the direction of the cutter, vibration and trembling of the supporting structure. Trouble is added by bending and curvature of the workpiece, which are associated with an increase in internal stress due to the sampling of wood. It is impossible to avoid all the shortcomings in the manufacture of a home-made copy-milling machine. It is simply recommended to make the copier narrow-profile, and not universal.

A homemade copy-milling machine should be optimized for the production of specific products that you need. For example, to effectively manufacture the wooden part of a gun and a propeller propeller, various technical solutions, they cannot be combined in one machine, and side effects that are difficult to correct may occur. Thus, it is more practical to assemble machines for some specific tasks. This approach can save you many costs and difficulties.

An important factor is the size of the machine. The larger the product you plan to process, the more massive the design should be. It is necessary that the vibrations that are transmitted from the drive of the cutter are absorbed by the weight of the supporting structure of the machine. The loads must be supported by the guide axles, which must also have a margin of safety and not sag. Optimal parameters when designing a copy-milling machine, they are selected empirically with their own hands, this ensures a smooth running of the cutter.

When designing a copy-milling machine, determine the type of parts that you will manufacture. To perform engraving work and to mill long products, a different worktable and method of fixing blanks with a template on it are required. Freedom of movement in different planes of the cutting tool depends on the type of desktop.

The power of the electric motor that rotates the cutter and is installed on a home-made copy-milling machine depends on the parts being manufactured and their material. For engraving and milling wood products, a 150-200 watt DC electric motor is enough.

To ensure the exact copying procedure, it is necessary to rigidly connect the copying probe and the device with each other, fixing the cutting tool in it. At the same time, their height and planes above the desktop must coincide completely. The created rigid structure should be installed above the desktop in such a way that it can move in the vertical and horizontal plane along the axes that are conditionally created by the sides of the desktop.

If you need to make a copy of an object made of wood or metal, copying equipment comes to the rescue; for this, it is used in many enterprises. In particular, copy-milling installations are designed to create objects that replicate the original sample as much as possible.

Modern types of machines make it possible to perform work accurately and quickly in large quantities. These setups are great to create copy jobs on the plane and in volume using appropriate copiers and volumetric models. What is a wood milling and copying machine, how it works and what is its approximate price, we will learn from the article.

Machine tools of this type are one of the methods of machining in order to create objects of the desired geometric shape. The workpiece surface is processed in several stages - roughing, semi-finishing and finishing.

The scope of milling machines is very wide - these are shaped parts made of wood, planar milling, profile processing, volumetric milling of reliefs of objects and parts. Before going into mass production, milling machines must pass special certification to comply with all safety standards and regulations required in the course of work.

Thanks to the technique of copying template technology, the same shape of all parts is obtained and the error of the worker servicing the machine is reduced to zero, since the person does not affect the working process of the unit.

To make a series of exactly the same finished products special templates required or a product that was made according to it. Experts recommend equipping the unit with an additional pantograph. This is a mechanism that transmits the movements of the cutting tool along the profile of the head setting as accurately as possible.

Processing the workpiece on the copier by means of a copy mechanism gives a command to all the actuators of the unit. The milling cutter of the installation and the part that is being milled recreate the surface specified on the copier in relative motion.

The main movements include - the desktop of the milling machine, movement along the contour of the sled, rotation of the spindle. The secondary ones are:

Copy milling can be of two types:

Contour milling is different in that when processing wood copier curve located in a parallel or perpendicular axis working tool. In one case, the working surface with the workpiece and the copier moves only in the parallel or transverse direction of the copier, its curved line. Also, they can only move longitudinally, in which case the entire curve process is controlled by moving the copy finger and cutter in a vertical plane.

Contour milling is different in that when processing wood copier curve located in a parallel or perpendicular axis working tool. In one case, the working surface with the workpiece and the copier moves only in the parallel or transverse direction of the copier, its curved line. Also, they can only move longitudinally, in which case the entire curve process is controlled by moving the copy finger and cutter in a vertical plane.

When the volumetric copying process is in progress, the workpiece has a spatially complex surface. It is machined with two or more parallel strokes of the worktable, contour milling is performed in each stroke. The working tool of the machine which is carrying out all process, after each working pass forced to move relative to the part to the cross feed indicator perpendicular to the line, then the table travel is performed again.

This equipment has long been indispensable for small furniture workshops. They help to mill straight lines and curved surfaces, drill holes, make nests of the most different configurations on wood.

This equipment has long been indispensable for small furniture workshops. They help to mill straight lines and curved surfaces, drill holes, make nests of the most different configurations on wood.

They are used for carving different types of wood, for copying sculptures and flat-relief surfaces. Machine tools help to significantly improve the quality of processed products. The main advantages of copy-milling machines for wood can be called:

Equipment designed for surface treatment soft and hard woods, so they are perfect for carpentry and model workshops.

Equipment designed for surface treatment soft and hard woods, so they are perfect for carpentry and model workshops.

Milling and copying units made in Italy G 60 - G 80 - G90 GRIGGIO, very popular in carpentry and furniture production. They are designed for milling curved and straight contours, sockets, contours and grooves, drilling and countersinking holes in carpentry and furniture blanks. Great for processing furniture facades and door panels. The size of the desktop is 750x600 mm, the vertical stroke of the desktop is 150 mm, the spindle movement in the vertical plane is 80 mm, the spindle rotates at a frequency of 9,000-18,000 rpm. The approximate price is 339,000 rubles.

Milling and copying machine VFK-810 (table rotation angle up to 45 o) - designed for milling curved and straight contours, nests, grooves, countersinking and drilling holes in furniture and carpentry blanks. An important advantage is the high speed up to 20,000 rpm, the ideal quality that the spindle gives. Table lift - 200 mm, its size, length - 1000 and width - 800 mm. The approximate price is 274,000 rubles.

Milling and copying unit WINNER LH-1000 made in Taiwan - perfect option for the manufacture of panel doors and other types of carpentry. Such operations are the most complex, time-consuming, therefore, even an experienced master with a high qualification is not able to cope with such a task for a short time. Produces a panel element in one pass, a multi-level spindle changes profile quickly without rearranging the tool. Equipped with a special table with a flat coordinate system, which ensures high accuracy of all milling operations performed, as well as safety. The spindle rotates at a frequency of 9,000 rpm, the price of the machine is 1,246,463 rubles.

Copy-milling machine made in China MX 5068. Its distinctive features are high speed up to 18,000 rpm, the spindle gives the ideal quality, products do not need further processing. Vertical movement of the spindle from a pneumatic drive, table rotation by 45 °, increased dimensions of the working table - 805-600 mm, the greatest thickness of the workpiece - 150 mm, machine weight - 440 kg, product price - 193,240 rubles.

Equipment such as modern copy-milling machine is characterized by high precision and reliability in execution various kinds works. In order to start working on it, 2-3 days of training is enough, after which you can create real masterpieces on wood.

Wood is one of the main materials that people use in Everyday life for the manufacture of furniture, objects interior decoration, decorative architectural elements, household and garden supplies and much more.

Wood copier.

One or two things can be done hand tool or using woodworking equipment.

But how to process a large number of completely identical products with the least labor and time costs? In this case, copy machines will come to the rescue. One of them is a copy-milling machine for wood.

The article discusses its device and principle of operation, and also offers some advice to those wishing to make the device on their own.

Copy-milling machines (CFS) are designed for processing wood parts by copying. Varieties of the method:

One method or another is used depending on the shape of the workpiece.

The main advantage of copy machines is that you can produce any number of parts with a curved contour, which are a copy of the original copy. All of them will be absolutely identical. At the same time, the machine has the flexibility to switch to another part, just change the reference.

Therefore, their scope is quite wide: from small-scale production to mass production. In addition to large enough machines for industrial use, there are also compact bench-top devices. Copy machines are used in furniture production, woodworking shops, in carpentry workshops of individual entrepreneurs.

Milling heads (milling cutter) are often used as a working unit in small machines. Its rotational speed is sufficient to ensure the required surface quality (no chips, splits, burrs).

Below is a far from complete composition of products manufactured using FSC:

As you can see, the listed parts have significant differences from each other, both in size and shape. If you group them according to the most common features, then it becomes obvious that processing of parts belonging to the same group requires its own design (layout) of the machine.

For replication of the product, one of the copies is used, which serves as a template. The head with the cutting tool (cutter) is integrally connected to the copy probe.

In 2D milling, the probe moves along the generatrix of the copied contour, and the rotating tool repeats this movement, resulting in a copy of the template.

When milling a 3D part, the copy tip scans the 3D model and causes the cutter to move along an equidistant (similar) path. The nature of the movements of copying machines is of 2 types:

A private type of copying and engraving work is the milling of drawings or ornaments according to a template, which is a pasted paper copy printed on a printer.

As a program for creating a drawing, you can use AVTOCAD, Compass, Word, Paint and others. In order not to break through the paper, a soft insert (wood or plastic) is inserted into the copying tip.

What you need to know when starting to develop your original device.

First of all, you should determine what parts it is intended for. Next, you should select the shaping movements, the number of axes of the machine. For processing flat parts by contour copying, 2 axes are sufficient: longitudinal and transverse movement. Details with low relief require another movement (perpendicular).

However, if the terrain is steep, then the tool axis must be additionally rotated to provide better conditions for processing. That is, it already turns out 4 axes. In some cases, 5 or more axles will be required. Introducing processing technology in your head, you should consider all possible situations. After the machine has been manufactured, adding additional movements can be problematic.

Finally, the machine must be arranged in such a way that the control forces are minimal. This means moving parts should be as light as possible. Think about which layout is better to choose: horizontal or vertical. Firstly, the convenience of work, as well as loading and unloading of workpieces, depends on it. Secondly, with a vertical layout, the chips fall directly to the floor or into the trough, and do not accumulate on the base or in the mechanisms of the machine.

The milling head should be selected as high as possible. This is an important factor affecting the quality of processing (the height of the scallops from the cutter decreases).

Photo 1: machine for cutting letters.

Used for flat threads. Its design is based on geometric figure- parallelogram. One of the properties of this mechanism is that the nodal points describe equidistant curves during movement. Moreover, if the link is lengthened, then its end point will cover a greater distance. This property allows you to use the mechanism for scaling.

The photo shows that the total length with a copying tip at the end is about 2 times longer than the side of the parallelogram. This means that the mechanism is increasing. If you copy any figure with the tip, the cutter will reduce it by 2 times. This will reduce copier errors. Do not forget that the drawing or template is enlarged in this case.

To make a pantograph, you will need a purchased milling cutter and several dry boards. Apparently it doesn't get any cheaper.

Photo 2: contour milling

The scope is also contour milling.

Unlike a pantograph, a curvilinear trajectory is obtained by adding 2 mutually perpendicular movements. The 3rd axis is used to insert the cutter into the thickness of the part. The weight at the opposite end of the swing frame is designed to balance the system.

Pay attention to a small flaw in the design: it is better to install the load on a threaded stud in order to provide for the possibility of adjustment.

Photo 3: volumetric milling

In the lower part of the bed there are 2 swivel attachment points for the copier and the workpiece.

The milling head is mounted on a balanced oscillating frame, which moves along mutually perpendicular guides during operation.

Instead of linear bearings or sleeves, as in the previous device, roller carriages are used here. The advantage of the design is the open base, which facilitates the removal of chips.

Photo 4: machine for flat-relief and sculptural carving

Serial machine for flat-relief and sculptural carving. An example of simplicity: they say about such constructions - two sticks, two rolling pins. Has 5 controlled axes:

Longitudinal movement is obtained by adding 2 turns: levers and frame. As a power head, a German milling cutter with a power of 500 W and a spindle speed of 10 - 30 thousand revolutions per minute is used. Easily carried by one person (weight - 28 kg).

Photo 5: processing of long volumetric threads

2 more guide rollers (additional linear axis) are added to the previous machine, and the rotary work tables are arranged vertically. As a result, it became possible to process long volumetric threads.

Below are some drawings that may be useful when making a homemade device.

All the devices discussed above have manual control, that is, despite the increase in productivity, the person remains chained to the mechanism. Such work is rather monotonous and tedious. In mass and large-scale production, copy-milling machines equipped with numerical control (CNC) are used. All work on such equipment is reduced to loading blanks and removing finished products. As an example, the photo shows a similar machine.

The copier differs from a conventional CNC milling machine in the presence of a programming system. A traditional CNC machine works from a control program compiled by the operator in a system, for example, ARTCAM, according to a 3-D model that is developed at the design stage by a design engineer. If the product was created by a sculptor or designer, it must first be digitized, that is, a 3-D model must be created. This work is done by a software engineer.

The copier differs from a conventional CNC milling machine in the presence of a programming system. A traditional CNC machine works from a control program compiled by the operator in a system, for example, ARTCAM, according to a 3-D model that is developed at the design stage by a design engineer. If the product was created by a sculptor or designer, it must first be digitized, that is, a 3-D model must be created. This work is done by a software engineer.

On a CNC copy machine, the control program is compiled by the system itself. When installing a copied product, an additional CNC attachment probes the part and creates its 3-dimensional model, according to which the control program is automatically generated. Given the high cost of components, the problems with acquiring a CNC system, making your own CNC copy machine is something out of the realm of fantasy. It’s easier to make a CNC milling machine (not a copy machine), although not everyone can handle it either.

For those who are going to start their own business, making wood crafts, as well as for professional cabinetmakers, a do-it-yourself copy machine will be of great help. It can be successfully used for the purpose of decorating a country estate, outbuildings, playgrounds and other structures. Jewelry, it would seem, the work will be done effortlessly and with high quality.

The copy-milling machine for wood is designed to create products according to a given pattern. With the help of such devices, flat-relief, volumetric or sculptural carving is carried out. If it is not possible to purchase a factory model, then you can always make a machine with your own hands.

According to the degree of automation, three groups of copy-milling machines for wood are distinguished:

On the devices of the first group, the workpiece is fixed mechanically. The design of milling machines of the second and third categories provides for the presence of pneumatic clamps that hold the product. This allows you to work with aluminum.

Copy-milling machines for wood are designed for processing flat and voluminous parts. With the help of such devices, ornaments and inscriptions, shaped profiles, complex patterns on workpieces with faces in different planes are created.

There are models of CNC milling machines that process curved parts using the pattern copying method. Through the use of these devices, possible creation a large number of parts of complex shape and the same size.

Such machines are mainly used in furniture production to create decorative elements of complex shape.

In addition to furniture, decor items, architectural elements (bas-reliefs, friezes), souvenirs, wooden details weapons, handles of garden tools. Since all these products differ in shape and size, each of them requires milling machines of a certain design to create them. But regardless of the layout, all devices work on the same principle.

To work with wood, a milling cutter is installed on the machine - a cutting tool. Processing of products is carried out according to the following scheme:

Milling on a copy machine can be done by one of two methods:

The cutter on such devices can be made of mineral ceramics, synthetic or superhard material and can replace the grinding procedure. But for machines working with wood products, this is not very relevant, since this material is not particularly hard.

Buying a copy-milling machine for wood, especially equipped with a CNC, is beneficial for large manufacturers, in other cases it is easier to create it yourself.

Before manufacturing the machine, it is necessary to create a drawing and decide how the device will be used. If you plan to work with large products, then the size of the machine must also be large so that the cutter produces less vibration. In addition, you need to choose an electric motor of sufficient power. The choice depends on the density of the material with which you plan to work.

The number of axes is also determined at the layout stage, since changing the design of the finished machine can be problematic. To work with flat parts two axes are sufficient: with longitudinal and transverse movement. Workpieces with a small relief also require a perpendicularly moving axis. For processing more complex products, four or five axes may be needed.

There are many designs of a milling machine, but they all consist of three elements:

The design of the working surface of the copying machine must provide for height adjustment, and the milling head must be high-speed and equipped with an electric drive.

The layout of the copy-milling machine for wood can be vertical or horizontal. The comfort of working with the tool and unloading of finished parts depends on this.

Most cheap option, for the manufacture of which several boards and a milling cutter are needed. Designed for flat carving.

The shape is similar to a parallelogram. Thanks to this design, when moving, the nodal points describe equidistant curves. To scale the device, the link is lengthened.

The side of a parallelogram is twice as long overall length with copy tip. Because of this feature, when copying a part with a tip, the cutter will halve it, which reduces the error of the copier.

Used for contour milling. Unlike the previous model, a curvilinear trajectory is achieved by adding two axes perpendicular to each other. The third axis drives the cutter into the workpiece.

To balance the system, the design includes a counterweight on the other side of the swing frame. To be able to adjust, it is better to place it on a threaded stud.

On such a device, the milling head is placed on a swinging frame, which during processing moves on roller carriages along perpendicular guides. The model and part are mounted on two swivel nodes at the bottom of the base. The open bed makes it easy to clean out sawdust.

Serial copy-milling machine for wood, designed for both flat-relief and sculptural carving. The design provides for five controlled axles:

Quite light (weight about 28 kg) for one person.

The design of this model is similar to the Duplicarver-2, but it has two additional guide rollers (another linear axis), and the turntables are mounted vertically. Thanks to these changes, it became possible to work with long volumetric threads.

Although a manual wood router makes the job much easier and increases productivity, it still needs to be controlled. But the models used in mass production are equipped with numerical control (CNC). When working with such an apparatus, a person only needs to load the workpiece and pick up the finished part.

A simple CNC milling machine operates from a control program that the operator creates in a special system, according to a three-dimensional model developed in advance by a design engineer.

Unlike a simple CNC milling device, a programming system is installed in copier models, which itself compiles a control program. Such devices have an additional CNC attachment, which feels the reference workpiece, develops its three-dimensional model, on the basis of which the control program is made.

The main problem in machine tools with numerical control is the high cost. For a small production, there is no point in such an apparatus, since the payback period should be no more than five years. At home, with CNC it is easier to make not a copy machine, but an ordinary milling machine, which, however, is also not an easy task.