INSTRUCTIONS AND PROPHECIES OF THE Blessed MOTHER ALIPIA GOLOSEEVSKY, Kyiv...

One of the main components of the automatic fire alarm system (APS) are fire detectors ( firefighters sensors), which serve as sensors for early detection of a fire source in a protected room. Since the initial stage of ignition can be different (smoke, elevated temperature, open flame, or something similar) and depends only on combustion products, fire detectors are divided into several types, each of which is most effective in terms of exposure to a certain sign of combustion at the initial stage of occurrence. fire. Thus, six main types of fire detectors are distinguished:

Also, the detectors are divided according to the way of eating:

according to the principle of reaction to the source of ignition:

where possible to determine the location of the fire:

by type of controlled area:

Based on this, it becomes clear that each detector is a separate device that has its own characteristics, construction structure, principle of operation and installation requirements. All this should be taken into account when choosing fire detectors, since their characteristics and correct installation will directly affect the effectiveness of the protection of your facility.

According to the current legislation, namely set of rules SP 5.13130.2009, The placement, number and type of fire detectors in a controlled room is strictly regulated and must meet the following requirements:

1. required amount fire detectors, determined by the area of the controlled premises;

2. in each room of the protected object, at least two fire detectors must be located, which are included in the system circuit according to the logical "OR" circuit;

3. It is allowed to install one fire detector in one room if the following conditions are met simultaneously:

The area of the controlled premises does not exceed the passport value of the controlled area of the selected detector;

The control panel (PPK) controls the health of the detector;

The detector has a light indication of a malfunction, and the duty personnel can replace it within the lines established by the regulations;

The fire alarm system does not issue a control signal fire automatics(starting fire extinguishing, notification, smoke removal) and the object does not use the 4th or 5th type of notification;

4. point fire detectors should be installed under the ceiling, so that no structures prevent the natural ingress of smoke or other combustion product onto its sensitive elements;

5. if the overlap of the monitored room has a slope of more than 10°, then the distance between the detectors can be increased by 20%, but other requirements must be observed SP 5.13130.2009;

6. point smoke detectors should be installed at a distance of at least 1 m from the ventilation openings so that air flows do not interfere with the natural spread of smoke;

7. If there are linear beams on the ceiling of the protected premises, the installation of smoke fire detectors should be carried out strictly adhering to the requirements of the following table:

8. If there are honeycomb-shaped beams on the ceiling of the protected room, the installation of smoke fire detectors should be carried out strictly adhering to the requirements of the following table:

9. when installing point, linear or aspiration detectors in warehouses with racks, the height of which reaches less than 0.6 m before overlapping, detectors are installed in each compartment formed by racks or stored materials;

10. when installing fire detectors in rooms with a width of less than 3 m (corridors) or a height of less than 1.7 m, the distance between them may be increased by 1.5 times the nominal one;

11. when installing fire detectors in spaces with limited access (raised floor, false ceiling, etc.), the optical identification of their operation must be brought out, while it is necessary to provide free access for their maintenance (technical hatch or something similar) ;

11. when installing fire detectors in spaces with limited access (raised floor, false ceiling, etc.), the optical identification of their operation must be brought out, while it is necessary to provide free access for their maintenance (technical hatch or something similar) ;

12. installation of any fire detector should be carried out in compliance with its technical documentation and in accordance with the requirements SP 5.13130.2009 on the given type detector;

13. when installing detectors in places where there is a risk of damage, they must be equipped with protection that will not interfere with the natural detection of the ignition factor;

14. in the case when it is not possible to accurately determine the dominant factor in the start of a fire in a room, combined fire detectors should be used or several detectors with different actions should be installed, while the installation is carried out in accordance with the requirements SP 5.13130.2009 for each detector separately;

15. if there is a perforated false ceiling in the controlled room, where the perforation occupies at least 40% of its area, the size of the perforation is not less than 10 mm, and its thickness is not more than three times the cell size, it is allowed to install detectors to control the room behind the false ceiling;

16. installation of fire detectors should be carried out so that their light indicators are directed towards the exit from the premises;

17. It is allowed to install special flowing fire detectors, which must control the ventilation ducts exhaust ventilation for smoke. Their installation is carried out strictly according to the manufacturer's requirements and only in cases where smoke can enter the ventilation before it is detected by a conventional detector.

Such detectors are installed in rooms where the dominant sign of the start of a fire is smoke. Smoke detectors, in addition to the main classification of all detectors, have their own classification, according to which they are divided according to the principle of action: ionization and optical, a by way of installation on:point, linear and aspiration. When installing such detectors, their sensitive elements or air intake pipes (in the case of aspiration sensors) should be placed under the ceiling of the monitored room, since smoke is much lighter than air and will always rise up.

When calculating the amount point smoke detectors and the choice of their installation site, all requirements must be followed SP 5.13130.2009 and follow the rules of the table below:

Linear smoke detectors have a design that differs significantly from that of a point fire detector. They consist of two elements (receiver and transmitter), the installation of which must be carried out on the walls before the ceiling, at a distance of 0.1 - 0.6 m from the level of the ceiling itself. It is also important to ensure that the optical beam generated by such a detector is not interrupted by any moving structures or elements of the floor itself (ledges, beams, etc.).

The use of such detectors is justified in rooms with high ceilings (up to 21 m), the length of which does not exceed 100 m. In this case, depending on the situation, two detector layouts are used: single tier and double tier.

Single tier layout used in rooms up to 12 m high, while the detectors are placed in such a way that the distance between parallel optical axes is no more than 9 m, and between the optical axis and the wall is no more than 4.5 m. It is also important to observe a distance of at least 0.5 m from the optical axis to various surrounding objects (lamps, ledges, etc.).

Bunk layout used in rooms with a height of 12 to 21 m, while the detectors are placed in accordance with the table below in two tiers:

It is also important to maintain a distance of at least 0.5 m from the optical axis to various surrounding objects (lamps, ledges, etc.).

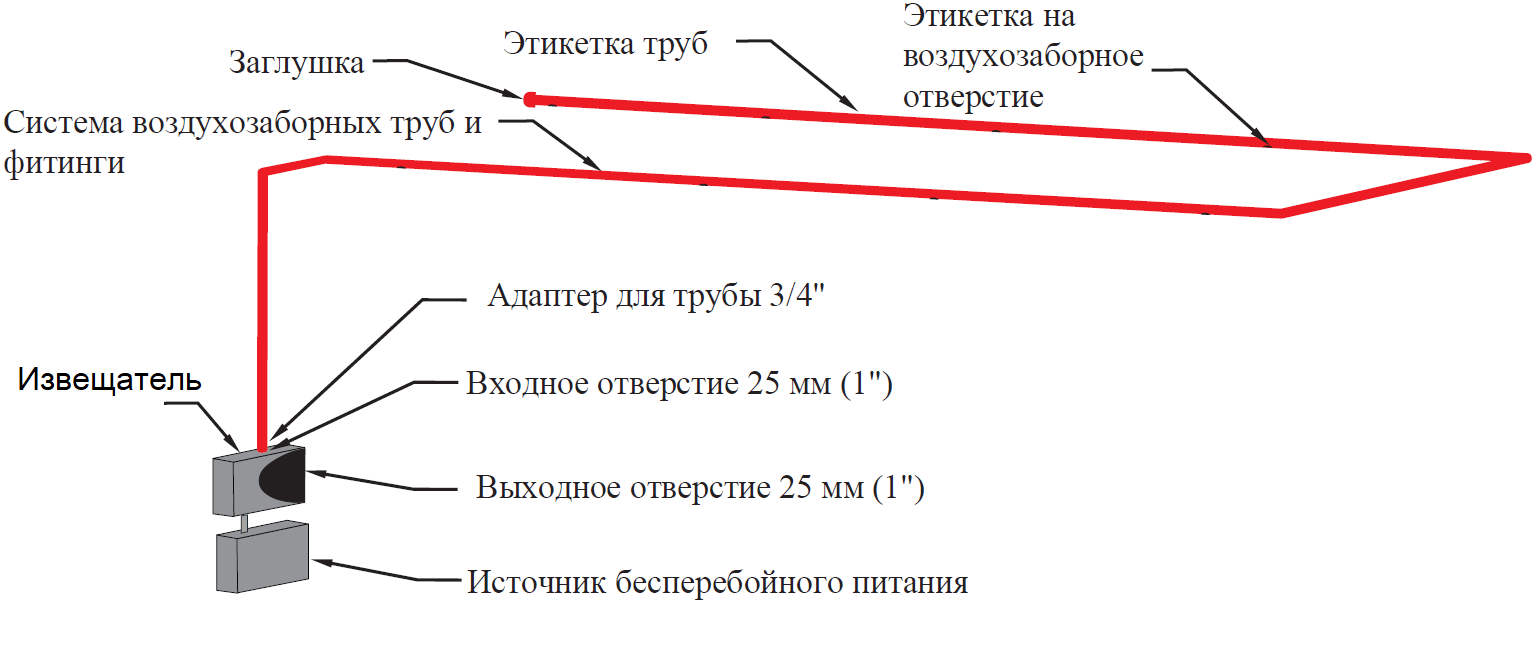

Aspirating smoke detectors are used to control large areas. The use of one such sensor allows you to protect an area of up to 1000 m 2, which makes it possible to significantly save on communications and installation work Oh. Such detectors are divided into three classes (A, B, C) depending on the level of sensitivity. Each level corresponds to a certain height of the air sampling tubes, which ultimately affects the final cost of the device.

Class A and B detectors have high sensitivity and are used in rooms with a ceiling height of more than 8 m. At the same time, air sampling tubes can be built into building structures or laid behind a false ceiling, with air sampling capillaries leading into the main space of the room. This solution allows, in addition to monitoring large areas, the use of these detectors in rooms with high requirements for the interior.

When laying air sampling pipes with holes that come from the unit aspiration detector, it is worth observing all installation requirements that apply to conventional point smoke detectors.

Such detectors are installed in rooms where the dominant sign of the start of a fire is an increase in ambient temperature. Heat detectors, in addition to the main classification of detectors, have their own classification, according to which they are divided according to the principle of fire detection on: maximum (slow temperature increase to the maximum value) and differential (rapid temperature change), as well as by way of installation on:point and line. When installing such detectors, their sensitive elements should be placed under the ceiling of the controlled room, since warm air quickly rises up and accumulates at the level of overlap.

When calculating the amount point thermal fire detectors and the place of their installation, all requirements must be observed SP 5.13130.2009 and follow the requirements of the table below:

The requirements of this table apply to the so-called square layout, when the detectors on the ceiling are placed in the shape of a square. This is the standard layout that is used in most cases. It should also be remembered that there is a scheme for installing detectors in a triangle, when the detectors form an equilateral triangle on the ceiling. Such a layout is more difficult to implement and is used only to protect large premises, for example, a closed parking lot or something like that.

Linear thermal fire detectors have a design that differs significantly from the design of a point fire detector. They are a special thermal cable, which is laid under the ceiling, or in direct contact with the fire load, while it is worth adhering to all the requirements and distances that are put forward for the installation of conventional point heat fire detectors. Also, such detectors are allowed to be used in warehouses with rack storage of products. In that case, for them maximum efficiency, sensitive elements (thermal cable) can be laid along the upper tier of racks.

Such detectors are installed in rooms where the dominant sign of the start of a fire is an open flame. Flame detectors, or as they are also called - light, in addition to the main classification of detectors, have their own classification, according to which they are divided by spectrum electromagnetic radiation on the: ultraviolet, infrared, multirange and visible spectrum detectors. According to the installation method, they are point and can be mounted on the floor of the building, its walls, building structures or process equipment that can catch fire during operation. When designing a system using flame detectors, it is especially important to take into account the initial stage of ignition, since if smoke is possible at this stage, then the detectors must be mounted at a distance of at least 0.8 m from the ceiling ( smoke collects before shutoff and may interfere with flame identification).

In accordance with current legislation, flame detectors must comply with the sensitivity class, according to which their range is determined. On the this moment There are 4 main classes:

1st class - up to 25 m;

2nd class - up to 17 m;

3rd class - up to 12 m;

4th class - up to 8 m.

It is also worth remembering that one zone must be controlled by at least two detectors, which are included in the circuit according to the logical “AND” scheme. It is allowed to install one fire detector in the event that the paragraph 3 of the requirements for the installation of fire detectors of this article.

Such detectors are installed in rooms where the dominant sign of the start of a fire is the accumulation of explosive gases, such as: CO 2 , CO or CH y . Gas detectors, in addition to the main classification of detectors, have their own classification, according to which they are divided according to the level of sensitivity to CO for 2 classes:

1st class - 20-40ppm;

2nd grade - 41-80ppm.

Installation of such detectors is carried out in accordance with the factory instructions and in accordance with the requirements of the table below:

Such detectors are used in cases where the dominant initial sign of fire is unknown or there may be several such signs, for example, smoke and high heat generation. Such a detector, visually, is practically no different from a conventional smoke detector, but contains a combination of several sensors, most often these are smoke and heat sensors.

To date, there has been new class combined fire detectors - multisensory, which react to all factors of a fire (smoke, heat, carbon monoxide(CO) and open flame). They have high noise immunity, which helps to avoid false alarms of the system and respond to any of the signs of a fire. Installation of such detectors is carried out in accordance with the factory instructions and in accordance with the requirements of the table below:

Installation of such detectors is carried out on the evacuation routes from the protected object, on the walls, at a height of approximately 1.5 m from the floor level. The main task of such a detector is to manually start the fire alarm system by a person who saw a fire at the facility. When installing, it is worth observing the requirements of fire safety standards, according to which the distance between adjacent detectors in the building should not exceed 50 m and 150 m on the street. Also Special attention it is worth paying attention to ensuring that access to the detector is not obstructed by foreign objects, and the installation site has sufficient lighting for its timely detection.

We continue the series of articles on the installation of a fire alarm system in a warehouse building materials. We have already talked about the installation of motion sensors (volumizers), today we will talk on the installation of smoke and heat detectors.

The calculation of the number of smoke detectors must be carried out based on the following table:

We install sensors at a height of about 3 meters, the area served by one sensor is about 25 square meters. m. It would be possible to install only one sensor, but then the distance to the walls would be too large. We select the necessary places in accordance with the table. In our case, the distance between devices is much less than 9 meters.

We fasten the device on self-tapping screws to wooden beam. Both smoke detectors are combined into one line and connected to one loop of the fire alarm controller, so we have two wires: one brings the signal and power, and the other leads them to the second sensor.

When installing, it is important not to get tangled in the wires! They have different colors (black and red). We connect them to the contacts of the corresponding color.

Now we connect the second sensor. Please note, here we install not only the wires, but also the shunt resistor. Let's not get into complex physical terms, but just consider the principle of operation of this resistor in the sensor.

The shunt resistor is connected to the same pins as the wires. It processes the current signal in the cable within a certain range. And when smoke appears, it is he who sends a signal to the controller - sends back less current.

This is what the assembled sensor looks like.

Heat detectors react to sudden changes in ambient temperature. Usually they are set to a temperature of about 75 degrees Celsius. In our case, disposable sensors are used (after they have been triggered, they must be replaced with new ones). The calculation is carried out according to the following table:

We also hook two heat detectors to one controller loop, so we install them in a chain. Power and signal are supplied to the first one, and wiring to the next sensor is diverted from it.

To the latter, we simply hook the wires, and that's it. No additional resistors are required.

We placed smoke and heat sensors at some distance from each other. They react to different signs of a fire (smoke and temperature increase), so it is not advisable to carry them to different angles.

You can test it with a regular cigarette. To do this, we bring a lit cigarette to the sensor and direct the smoke directly into it. If the system is properly installed and configured, an alarm will be generated.

It is not only not recommended to install alarm systems on your own, but it is also strictly PROHIBITED, since any mistake can cost several human lives. Therefore, if you need, contact the studio "We'll fix everything!"

For fire safety, fire extinguishers must be installed in the room. These are not empty requirements, these are fire protection measures. The very installation of fire detectors of various types belongs to a complex of specialized works. They are carried out in accordance with established norms and regulations. All requirements are spelled out in the thematic documentation of the Ministry of Emergency Situations. It is important to remember that installation and further maintenance must be carried out by companies that are licensed to carry out these activities.

To determine how much smoke detectors for a particular room, the following must be taken into account:

There is certain rules smoke detector installations. Sensors must be installed under the ceiling. If for some reason the arrangement is not possible in this way, then columns are used, devices are already installed on them. In addition to columns, walls and other supporting structures are allowed.

The documents do not specify the specific location of smoke detectors, but only indicate the distances from the partitions to the corners in the room. Therefore, they are usually installed in those places where the area will be covered to the maximum.

The documents indicate the necessary distances required when installing point smoke devices from ceilings to corners. They are the following:

If linear fire detectors are installed, then the rules are slightly different. They must be installed on partitions or columns so that the optical axis on the receiver and source is at least 10 cm from the ceilings. In this case, it should be taken into account that both the emitter and the receiver must be located on the structure in such a way that no other objects fall into the fire hazard detection zone during operation. Otherwise, they may cross the optical axis.

There are standards for the installation of fire detectors. Optical smoke devices are positioned so that the distance between the optical axis and objects is at least 50 cm. Only in this way can any interference be avoided and there will be no obstacles for fire detection.

This type is designed for autonomous detection of fires. It is powered by people. There are special installation rules. They depend on the type of device, on the room where the installation will take place.

According to the requirements, manual call points are mounted in places far from electrical or permanent magnets. Can't be placed near electrical appliances, which form around themselves magnetic fields. Because of this, in the future, violations in the operation of the detector mechanism and involuntary operation are possible if it is suddenly activated.

If the installation of manual sensors takes place in public or administrative buildings, where there are constantly a large number of people, then they should be installed in the following places:

If the installation of fire detectors takes place in cable structures (type - tunnels), then the installation should be near their entrance, at branches, emergency exits. It is important to remember that there is always free access to the device.

Before installation, you need to find out how many sensors should be in one room. The quantity is usually calculated taking into account that one device is installed on 30 sq.m. area. But the value may be different if other indicators are given in the technical data sheet. They may be more or less.

Basically, autonomous detectors are installed on the ceiling. If installation work cannot be done, then they are installed on a column or wall. However, the following distances must be taken into account:

Sometimes it happens that the ceiling structures are divided into separate parts. In such a situation, autonomous sensors are installed on each compartment. If there are protruding parts on the ceiling and their height is more than 8 cm, then the maximum controlled area of one sensor should be reduced by 25 percent.

There is no general standard regarding the installation height of fire detectors. But if some requirement. If the ceilings are multi-tiered and the height of some is more than 40 cm and the area is more than 0.75 sq.m, then it is necessary to install separate autonomous devices for detecting fires.

Do not install fire detectors in places where the sun's rays constantly fall. Unsuccessful will be a place near the supply ventilation system. At the place of installation work, the air flow speed of more than 1m/s is not allowed.

The importance of fire alarms cannot be overestimated. The owners of buildings and premises are not always responsible for installation and maintenance fire fighting systems. And almost always there comes a moment when they bitterly regret it.

The fire breaks out unexpectedly and sweeps away human lives, property, entire objects in its path. Therefore, it is extremely important to equip the premises with fire alarm and fire extinguishing systems, and then regularly monitor their performance.

The fire detector is the central element of the fire alarm system. The installation standards for detectors are described in NPB 88-2001 “Fire extinguishing and alarm installations. Norms and rules of design».

Some general installation requirements apply to different types of detectors:

For all types of fire detectors, there are specific installation rules and regulations that you should know and follow.

Fire sensors can respond to various signs of a fire: smoke, elevated temperature, open flames. On this basis, the detectors are divided into heat, smoke and flame detectors.

Point sensors can be attached to a tensioned cable, if the room is characterized large area. In this case, the devices must be securely fixed on the cable, and the distance from the ceiling finish to the bottom of the detector cannot exceed 300 mm.

When ceiling-mounted, the sensor is installed 10 cm from the wall.

If there is a high probability of mechanical damage to the detector, it is protected by a grill, cap or box that does not interfere with the operation of the device.

Heat and flame detectors are mounted in places where a sharp increase in temperature or the appearance of open fire respectively.

Wires for communication lines of fire alarm elements are also selected in accordance with the regulations. The design of laying wires and cables should provide for their integrity in the event of a fire and the possibility of automatic monitoring of the state along the entire length.

It is allowed to use only wires with copper conductors for fire detectors. A minimum of 10% cable reserve is required during installation.

Do not lay fire alarm wires together with power cables. It is also forbidden to fix the wires next to (closer than 50 cm) high voltage lines.

Manual call points are still often used to protect premises. Devices are installed in halls, corridors, lobbies, on landings and near each exit.

The installation site of the manual call point must be away from electric or permanent magnets and electrical appliances that generate magnetic fields.

Devices are installed at a height of 1.5 m from the floor level. It is necessary to organize a free approach to the detector and good lighting at the location of the device.

Over the past three years, many of the regulations governing the placement of fire detectors have changed twice. To replace NPB 88-2001* “Fire extinguishing and alarm installations. Design Codes and Rules" in November 2008, a new set of rules was issued SP 5.13130.2009 "Systems fire protection. Fire alarm and fire extinguishing installations are automatic. Design Norms and Rules”, which for the first time regulated the options for arranging detectors in rooms with sloping ceilings, with decorative suspended lattice ceilings, etc. Enacted on June 20, 2011, change No. significant adjustments, with some requirements returned from NPB 88-2001*. It is also necessary to note the fundamental differences in the requirements for the placement of fire detectors in our and foreign normative documents. Our standards, unlike foreign ones, contain only requirements, there is no explanation of physical processes. It breeds various interpretations, often erroneous, moreover, the main provisions have no theoretical justification. There are no formal grounds for choosing the most effective solution taking into account the physical processes of detecting fire factors in specific conditions. As a rule, the probability of evacuation of people and material damage in the event of a fire is not assessed when designing fire automation systems. Therefore, a long process of harmonization of our fire safety standards is ahead, and with a high probability we can expect the release of amendment No. 2 to the set of rules SP 5.13130.2009 in the near future, then amendment No. 3, etc. For example, it is quite possible that clause 13.3.7 of SP 5.13130.2009, according to which "the distances between the detectors, as well as between the wall and the detectors, given in tables 13.3 and 13.5, can be changed within the area shown in tables 13.3 and 13.5". The first part of the article discusses the placement of point fire detectors in the simplest case, on a flat horizontal ceiling in the absence of any obstacles to the spread of combustion products from the source.

physical processes

In the European Standard BS 5839 for Fire Detection and Alarm Systems for Buildings, Part 1 Code of Practice for the Design, Installation and Maintenance of Systems, each section and each paragraph first sets out the physical processes to which attention should be paid, and then how consequence, requirement. For example, why it is necessary to take into account the specifics of work and the type of automatic fire detectors when placing them.

“Heat and smoke detectors rely on convection to carry hot gas and smoke from the hearth to the detector. The location and spacing of these detectors should be based on the need to limit the time spent on this movement, and subject to sufficient concentration of combustion products at the location of the detector. Hot gas and smoke will generally be concentrated in the highest parts of the room, so this is where heat and smoke detectors should be located. Since the smoke and hot gases from the hearth rise up, they are diluted with clean and cold air, which enters the convective jet. Consequently, as the height of the room increases, the size of the source required to activate heat or smoke detectors increases rapidly. To some extent, this effect can be compensated for by using more sensitive detectors. Linear smoke detectors with an optical beam are less sensitive to the effect of a high ceiling than point type detectors, since with an increase in the smoky space, the length of the beam affected by smoke increases proportionally ...

The effectiveness of an automatic fire detection system will be affected by obstructions between heat or smoke detectors and combustion products. It is important that heat and smoke detectors are not installed too close to obstructions to the flow of heated gas and smoke to the detector. Near the wall-ceiling junction there is a "dead space" where heat or smoke detection will not be effective. Since the hot gas and smoke spread horizontally parallel to the ceiling, similarly there is a stagnant layer near the ceiling, this precludes installation with the location of the sensing element of the heat or smoke sensor flush with the ceiling ... ".

Rice. 1. NFPA 72 smoke distribution model

In the American fire alarm standard NFPA 72, explanations, reference data and calculation examples are given in appendices, the volume of which is almost 1.5 times the volume of the main text of the standard. NFPA 72 states that in the case of a flat horizontal ceiling and in the absence of additional air currents, the smoke forms a cylinder of a certain height centered on the projection of the hearth (Fig. 1). With distance from the center, the specific optical density of the medium and temperature decrease, which determines the limitation of the smoky space at the first stage of the development of the source.

Positioning requirements for point detectors per BS 5839

According to the BS 5839 standard, the protection radius for smoke detectors is 7.5 m, for heat detectors - 5.3 m in horizontal projection. Thus, it is easy to determine the placement of detectors in a room of any shape: the distance from any point in the room to the nearest smoke MT in horizontal projection should be no more than 7.5 m, from the thermal one - no more than 5.3 m. This value of the protected area determines the installation according to square grille of smoke detectors after 10.5 m, and for heat detectors - after 7.5 m (Fig. 2). Significant savings in the number of detectors (approximately 1.3 times) are achieved in large rooms when using the placement of detectors on a triangular grid (Fig. 3).

Rice. 2. Placement of smoke and heat detectors according to BS 5839

Rice. 3. Arrangement of smoke detectors on a triangular grid

Rice. 4. Placement of smoke detectors in a rectangular room

In extended rooms, it is also considered that the smoke detector monitors the area at a distance of no more than 7.5 m in horizontal projection. For example, in a room 6 m wide, the maximum distance between the detectors is 13.75 m and the distance from the detector to the wall is 2 times less, which is 6.88 m (Fig. 4). And only for corridors whose width does not exceed 2 m, the provision applies: only points closest to the center line of the corridor require consideration, respectively, it is allowed to install smoke detectors at intervals of 15 m and at a distance of 7.5 m from the wall.

NFPA 72 Point Detector Placement Requirements

According to NFPA 72, in the general case, on horizontal smooth ceilings, point detectors are placed in a square grid with a step S, the perpendicular distance from the wall to the detector should not exceed S/2. In addition, it is indicated that any point on the ceiling should be no further than 0.7S from the nearest detector. Indeed, the diameter of the circumference of the area protected by one detector when they are arranged on a square grid with a step S is equal to the diagonal of the square S x S, the value of which is S√2. Accordingly, the radius of the protected zone is equal to S√2/2, which is approximately equal to 0.7S.

Moreover, for thermal detectors, the step of the square grating S is calculated based on ensuring the detection of the source with power Q CR during time t CR so that by the time the extinguishing starts t DO or the AUPT is turned on, its value does not exceed the specified power Q DO , for example, not more than 1055 kW ( 1000 Btu/sec). The calculations take into account the quadratic dependence of the source power growth on time (Fig. 5). The appendices give examples of calculations and reference data on various types materials and products.

Rice. 5. Dependence of the power of the fire seat on time

With the initial value of the square grating spacing S = 30 feet, i.e. 9.1 m, it is assumed that the detector protects the area in the form of a circle with a radius of 6.4 m (9.1 m x 0.7). Based on this concept, NFPA 72 gives examples of the dimensions of rectangles that fit within a 6.4 m radius circle (Figure 6) and can be protected by a single detector located in the center:

Rice. 6. Rectangles inscribed in a circle with a radius of 6.4 m

A = 3.1 m x 12.5 m = 38.1 m2 (10 ft x 41 ft = 410 ft2)

H = 4.6 m x 11.9 m = 54.3 m2 (15 ft x 39 ft = 585 ft2)

C = 6.1 m x 11.3 m = 68.8 m2 (20 ft x 37 ft = 740 ft2)

D = 7.6 m x 10.4 m = 78.9 m2 (25 ft x 34 ft = 850 ft2)

The maximum area obviously corresponds to a square inscribed in a circle of 9.1 m x 9.1 m = 82.8 m2 (30 ft x 30 ft = 900 ft2). Placement of detectors in rooms rectangular shape recommended by dividing their area into rectangles that fit into a circle with a radius of 6.4 m (Fig. 6).

Rice. 7. Placement of detectors in rectangular rooms

In a non-rectangular room, the detector placement points can be defined as the intersections of circles with a radius of 6.4 m centered at the corners of the room furthest from the center (Fig. 7). Then, the absence of points outside the circles with a radius of 6.4 m with centers at the points of placement of the detectors is checked and, if necessary, additional detectors are installed. For the room shown in Fig. 8, it turned out that 3 point detectors were quite enough.

Rice. 8. Placement of detectors in non-rectangular rooms

British standard fire start

AT complex systems, where a false positive can lead to a significant material damage, additional measures are applied, including work on 2 detectors. For example, in the British standard BS 7273-1 on gas fire extinguishing in order to avoid unwanted release of gas in the case of automatic operation of the system, the operation algorithm, as a rule, should assume the detection of a fire simultaneously by two separate detectors. Moreover, the activation of the first detector should at least lead to the indication of the "Fire" mode in the fire alarm system and to the activation of an alert within the protected area. In this case, the arrangement of detectors, of course, should ensure the control of each point of the protected premises by two detectors with the possibility of identifying the activation of each of them. In addition, in this case, the fire alarm and warning system must be designed in such a way that, in the event of a single break or short circuit in the loop, it detects a fire in the protected area and, at least, leaves the possibility of manually switching on fire extinguishing. That is, if maximum area, controlled by a single detector, is X m2, then in the event of a single loop failure, each fire detector must provide control of an area of a maximum of 2X m2. In other words, if in normal mode double control is provided for each point of the room, then in case of a single break or short circuit of the loop, single control should be provided, as in a standard system.

This requirement is quite simply technically implemented, for example, when using two radial plumes with the installation of detectors in “pairs” or one ring loop with short-circuit insulators. Indeed, in the event of a break or even a short circuit of one of the two radial loops, the second loop remains in working condition. In this case, the arrangement of the detectors should ensure the control of the entire protected area by each loop separately (Fig. 9).

Rice. 9. Arrangement of detectors in "pairs" with inclusion in two loops

A higher level of performance is achieved when using ring loops in addressable and addressable analog systems with short circuit isolators. In this case, in the event of a break, the ring loop is automatically converted into two radial ones, the break point is localized, and all detectors remain in working order, which keeps the system functioning in automatic mode. In the event of a short circuit on the analog addressable loop, only the devices between two adjacent short circuit isolators are switched off. In modern analog addressable systems, short-circuit isolators are installed in all detectors and modules, so that even if the loop is short-circuited, the operation is not disturbed.

It is obvious that systems with one two-threshold loop used in Russia do not meet this requirement. In the event of a break or short circuit of such a loop, a “Fault” signal is generated, and the fire is not detected until the malfunction is eliminated, the “Fire” signal is not generated for one detector, which makes it impossible to turn on the fire extinguishing manually after receiving it.

Our norms: past and present

Our requirements for the placement of fire detectors were first defined a quarter of a century ago in SNiP 2.04.09-84 "Fire automation of buildings and structures." This document specified the standard distances between smoke and heat point detectors when installed on a square grid, which have not changed since then. According to 4.1 SNiP 2.04.09-84, fire alarm installations should have generated an impulse to control fire extinguishing, smoke removal and fire warning installations when at least two automatic fire detectors installed in one controlled room are triggered. In this case, each point of the protected surface had to be controlled by at least two fire detectors. Moreover, the maximum distance between the redundant detectors was equal to half of the standard, respectively, the detectors in the fire extinguishing systems were installed in “pairs” (Fig. 9), which ensured the strict implementation of double control of the area of the room and the close response of the detectors in case of fire.

The control of technological, electrical and other equipment, blocked with the installation of a fire alarm, was allowed to be carried out when one fire detector was triggered. But in practice in simple installations fire alarm, the notification was switched on from one detector with a single control of the area of \u200b\u200bthe premises and the placement of detectors at standard distances. A separate paragraph contained a general requirement: "At least two automatic fire detectors should be installed in one room." And until now, the fulfillment of this requirement implies, as it were, the redundancy of fire detectors, which is actually provided only in small spaces, the area of which does not exceed the standard for one detector. Moreover, the illusion of redundancy creates the basis for the almost complete absence Maintenance, and even more so, there are no requirements for periodic monitoring of the sensitivity of detectors, respectively, test equipment is not produced. For example, in a 9 mx 27 m room with 3 conventional smoke detectors, to ensure redundancy, one detector must have a protected zone radius of more than 14 m and provide control of the entire room, i.e. 243 m2. Any of the extreme detectors can fail uncontrollably, and the malfunction may not be detected for several years.

But in practice, equipment of the same type has approximately the same time between failures, which determines the almost simultaneous failure of all detectors in the room and in the building. For example, there is a loss of sensitivity of all smoke detectors due to a decrease in the brightness of the optocoupler LEDs. Moreover, such a massive failure of domestic fire detectors is defined by GOST R 53325-2009 “Fire fighting equipment. Technical means of fire automatics. General technical requirements. Test methods”, since “the mean time between failures of fire detectors must be at least 60,000 hours”, i.e. less than 7 years, and “the average service life of a fire detector must be at least 10 years”.

The “area controlled by one detector” indicated in tables 4 and 5 of SNiP 2.04.09-84 is quite rightly indicated in today’s SP 5.13130.2009 as “the average area controlled by one detector”. However, for 25 years, we have not yet determined the maximum area protected by one detector in the form of a circle with a radius of 0.7 from the standard distance. Instead, in SP 5.13130.2009, clause 13.3.7, very strange in content, appeared, according to which “the distances between the detectors, as well as between the wall and the detectors, given in tables 13.3 and 13.5, can be changed within the area given in tables 13.3 and 13.5"?! That is, not like in NFPA 72, rectangles inscribed in a circle with a radius of 0.7 from the standard distance, but any aspect ratio of a rectangle with a constant area. For example, for smoke detectors with a room height of up to 3.5 m and a width of 3 m, the distance between the detectors can be increased to 85/3 = 28.3 m! Whereas, according to NFPA 72, the average area controlled by the detector in this case is reduced to 38 m2, and the distances between the detectors should not exceed 12.5 m (Fig. 6), in addition, paragraph 13.3.10 remained in SP 5.13130.2009 , according to which “when installing point smoke detectors in rooms with a width of less than 3 m, the distances between the detectors indicated in Table 13.3 can be increased by 1.5 times”, i.e. only up to 13.5 m.

Near future

Over the past decade, the development of our standards has been determined by the fight against false alarms of domestic fire detectors, moreover, without regular maintenance. Moreover, the requirements for the protection of detectors from external influences, which have not met the operating conditions for a long time, are not planned to be increased. But our DIPs are the cheapest in the world, however, and they can only be certified by us in accordance with GOST R 53325-2009. Even in neighboring countries, they switched to European standards of the EN54 series, the scope of tests and requirements in which are much higher. But at the same time, installation requirements are simplified: effective protection and high reliability eliminate the mandatory requirement to install at least two detectors of any type, and even detectors without automatic health monitoring are installed one at a time in the room. For fire alarms, the placement of detectors is based on a single control of each point of the protected area, in case of fire extinguishing - double.

But it turns out that we have not yet implemented all the ways to increase the reliability of the “Fire” signals. In the draft of the new edition of GOST 35525, the “Fire” signal from any threshold fire detector is perceived by the control panel as false and can only identify it as “Attention”. It is allowed to generate a “Fire 1” signal only either from one detector, if the “Fire” mode is confirmed after a re-request, or from 2 detectors without a re-request, if they are activated for a time not exceeding 60 s. The “Fire 2” signal, which is required by clause 14.1 of the set of rules SP 5.13130.2009 for generating signals for automatic control of fire extinguishing, smoke removal, warning or engineering equipment, in the general case should be generated only by two “Fire 1” signals per time no more than 60 s. Moreover, this algorithm for the formation of the Fire 1 and Fire 2 alarm control panels must be performed when working with threshold detectors of any type: thermal maximum and maximum differential, linear smoke, flame and thermal cable, since other algorithms for these detectors are not provided.

. Thus, protection against false positives has the highest priority for us and its increase is carried out by reducing the level of fire safety. When will the "Fire 2" signal be generated when implementing this algorithm? In most cases, never, and for several reasons. The set of rules SP 5.13130.2009 in this case prescribes the installation of detectors in increments of half the standard. That is, the detectors are located at different distances from the source, and their activation with a difference of 1 - 2 minutes. unlikely. For a technically competent implementation of the proposed algorithm, the detectors must be in close proximity, i.e., they must be installed in “pairs”, and taking into account the failure of one of them, in “triples”, moreover, with the same orientation to the air flow to eliminate the spread in sensitivity from the direction of the air flow, as shown in Fig. 10 Photoshop tools.

Rice. 10. Arrangement of fire detectors in "threes"

In addition, for the simultaneous operation of the detectors, it is necessary to install detectors with exactly the same sensitivity in “triples”. Even an allowable discrepancy between detectors in sensitivity by 1.6 times will determine the difference in response of several minutes with smoldering fires. Therefore, it will be necessary to accurately measure the sensitivity of each detector and indicate it on the label. The manufacturer will have to select packs of detectors with the same sensitivity. Naturally, it is necessary to ensure the stability of the sensitivity level during operation, not only due to circuit solutions and the choice of the element base. Absolutely identical operating conditions must be provided, up to the same dusting of the smoke chamber. Obviously, for smoke detectors, it will be necessary to introduce mandatory precision dust compensation. Etc.

Moreover, our 2-threshold control panels issue one signal with one relay, no matter how it is called, either one by one or by two detectors and already, as a rule, with a re-request. Moreover, the duration of the re-request, oddly enough, is not limited by the norms and already occurs 2 minutes. and more. Therefore, when the first detector is triggered, even after a re-request in our 2-threshold control panels, the output signal is not generated, therefore, ventilation, air conditioning, thermal curtains etc. are not turned off, which significantly affects the distribution of smoke and will determine a significant delay in the operation of the second detector, if it is located on long distance from the first. With open fires, the temperature in the room rises rapidly, and with a significant amount of time spent on re-requests, it is likely that the "Fire" mode will not be confirmed by the detector due to high temperature. Please note that most fire detectors have an operating temperature range of no more than 60 degrees C.

What happens with a false positive? Practice shows that low-quality detectors "false" in normal conditions, even though it is re-requested. In addition, any smoke detector in the absence of maintenance at high level dusting of the smoke chamber goes into operation, despite the resets. According to this algorithm, after 60 seconds, subsequent signals from other detectors are considered false alarms. Thus, one faulty detector disrupts the operation of the entire loop, and possibly all loops, depending on the design of the control panel. Moreover, this is a well-known property of all threshold devices and it is not clear why it is not taken into account in the standards. Why is there no time limit for troubleshooting in threshold fire systems? In the "Methodology for determining the calculated values of fire risk in buildings, structures and structures of various classes of functional fire hazard", the probability of effective operation of the fire alarm system is allowed to be taken equal to 0.8. This means that during a service life of 10 years, it is completely inoperable for 2 years, or an average of 2.4 months each year. And according to statistics, the efficiency of fire alarm installations during fires is even lower: in 2010, out of 981 installations during a fire, only 703 completed the task, that is, they worked with a probability of less than 0.72! Of the remaining 278 installations, 206 did not work, 3 did not complete the task (21.3% in total) and 69 (7%) were not turned on. In 2009, it was even worse, out of 1021 installations, only 687 completed the task, with a probability of 0.67!!! For the remaining 334 installations: 207 did not work, 3 did not complete the task (20.6% in total), and 124 (12.1%) were not included. Why not extend the action of SP 5.13130.2009 of the application "Determining the set time for detecting a malfunction and eliminating it" to threshold systems? After all, here we are not talking about one room with one addressable analog detector, but from several rooms to entire objects without automatic fire protection. How will the current situation change with the introduction of a new edition of GOST 35525? "Lozhnyak" will finally defeat the fire?

So, it seems that the development of fire systems in this direction is coming to a logical conclusion. The cost of cheap detectors will be too expensive. In the draft new edition of GOST 35525, fire tests of fire detectors on test sources were introduced into the certification test program. Finally find out what level of fire protection our fire detectors provide. Moreover, if the requirements for re-requests in the control panel remain in GOST 35525, then tests in without fail must be carried out with two maximum time retransmissions to simulate the detection of a fire by our decoy-proof devices.

Over the past three years, many of the regulations governing the placement of fire detectors have changed twice. It is also necessary to note the fundamental differences in the requirements for the placement of fire detectors in our and foreign regulatory documents. Our standards, unlike foreign ones, contain only requirements; they do not contain any explanation of physical processes. Amendment No. 1 to the set of rules SP 5.13130.2009 made significant adjustments, and some requirements returned from NPB 88-2001 *, and some, introduced for the first time, partially coincide with the requirements of foreign standards. For example, in clause 13.3.6 Amendment No. 1 to SP 5.13130.2009 it is said that "the horizontal and vertical distance from the detectors to nearby objects and devices, to electric lamps, in any case, must be at least 0.5 m", but not it is indicated what sizes of objects should be taken into account. For example, does this paragraph cover the cable that is connected to the detector?

In the first part of the article, the arrangement of point fire detectors was considered in the simplest case, on a flat horizontal ceiling in the absence of any obstacles to the spread of combustion products from the source. The second part discusses the placement of point fire detectors in real conditions, taking into account the influence of surrounding objects in the room and on the floor.

Obstacles to the impact of fire factors on detectors

In the general case, with a horizontal overlap, due to convection, hot gas and smoke from the hearth are transferred to the overlap and fill the volume in the form of a horizontally located cylinder (Fig. 1). When rising up, the smoke is diluted with clean and cold air, which is drawn into the updraft. Smoke occupies the volume in the form of an inverted cone with a vertex at the location of the hearth. When propagating along the ceiling, the smoke also mixes with clean cold air, while its temperature decreases and lift is lost, which determines the limitation of the space filled with smoke on initial stage fires in large rooms.

Obviously, this model is valid only in the absence of extraneous air flows created by supply and exhaust ventilation, air conditioners and in a room free from any objects on the floor near the paths for the spread of the smoke-gas-air mixture from the source of the fire. The degree of impact of obstacles on smoke flows from the source depends on their size, shape and location relative to the source and the detector.

Requirements for the placement of fire detectors in rooms with racks, with beams and with ventilation are present in various national standards, but differ significantly depending on the origin, despite the generality of physical laws.

Requirements of SNiP 2.04.09-84 and NPB88-2001

The requirements for the placement of fire detectors were first defined in 1984 in SNiP 2.04.09-84 “Fire automation of buildings and structures”, these requirements were set out in more detail in NPB 88-2001 “Fire extinguishing and alarm installations. Design norms and rules, as amended in NPB88-2001*. Currently, the set of rules SP 5.13130.2009 with Amendment No. 1 is in force. It is obvious that the development of new versions of documents each time was carried out on the basis of the previous one by adjusting individual clauses and adding new clauses and applications. For example, we can trace the development of our requirements over a 25-year period regarding the placement of detectors on columns, walls, cables, etc.

The requirements of SNiP 2.04.09-84 regarding smoke and heat fire detectors say that “if it is impossible to install detectors on the ceiling, it is allowed to install them on walls, beams, columns. It is also allowed to suspend detectors on cables under the coverings of buildings with light, aeration, skylights. In these cases, the detectors must be placed at a distance of no more than 300 mm from the ceiling, including the dimensions of the detector. In this paragraph, the requirements for the distance from the ceiling for various conditions placement of fire detectors relative to the directions of air flows and the maximum allowable distance for heat and smoke detectors. According to the British standard BS5839, fire detectors must be installed on the ceiling so that their sensing elements are located below the ceiling in the range from 25 mm to 600 mm for smoke detectors and from 25 mm to 150 mm for heat detectors, which is logical in terms of detecting various stages of development of the focus. Unlike smoke detectors, heat detectors do not detect smoldering fires, and at the stage of open fire there is a significant increase in temperature, respectively, there is no stratification effect and if the distance between the ceiling and the temperature-sensitive element is more than 150 mm, this will lead to an unacceptably late fire detection, i.e. i.e. will make them practically inoperable.

On the other hand, if detectors suspended on cables and mounted on the lower surfaces of beams are affected by horizontal air currents, then when placed on walls and columns, it is necessary to take into account the change in the direction of air currents. These structures are obstacles to the horizontal spread of smoke, thus forming poorly ventilated areas in which the placement of fire detectors is not allowed. The NFPA shows a drawing indicating the area where detectors are not allowed to be installed - this is the angle between the wall and the ceiling with a depth of 0 cm (Fig. 2). When installing a smoke detector on a wall, its upper part should be at a distance of 10–30 cm from the ceiling.

Rice. 2. NFPA 72 Requirements for Mounting Smoke Detectors on a Wall

A similar requirement was later introduced in NPB 88-2001: “When installing point fire detectors under the ceiling, they should be placed at a distance of at least 0.1 m from the walls” and “when installing point fire detectors on walls, special fittings or fastening them on cables should be placed at a distance of at least 0.1 m from the walls and at a distance of 0.1 to 0.3 m from the ceiling, including the dimensions of the detector. Now, on the contrary, the restrictions for placing detectors on the wall have been applied to detectors suspended on a cable. In addition, for some reason, the mention of “special fittings” was often associated with the installation of detectors on the wall and special brackets were designed for mounting the detectors in a horizontal position, which, in addition to additional costs, significantly reduced the efficiency of the detectors. The air flow, in order to get into the horizontally oriented smoke chamber of the detector mounted on the wall, must, as it were, go “into the wall”. At relatively low speeds, the air flow smoothly flows around obstacles and “wraps up” near the wall without going into the corner between the wall and the ceiling. Therefore, a horizontally mounted smoke detector on the wall is transverse to the airflow, as if the detector were installed vertically on the ceiling.

After adjustment two years later, in NPB 88-2001 *, the requirements were divided: “when installing point detectors on walls, they should be placed at a distance of 0.1 to 0.3 m from the ceiling, including the dimensions of the detector” and the maximum allowable distance of the detector from the ceiling when the detectors are suspended on a cable: “the distance from the ceiling to the bottom point of the detector should be no more than 0.3 m.” Naturally, if the detectors are installed directly on the ceiling, then when they are suspended on a cable, there is no reason to take them away from the ceiling by 0.1 m, as when placed on a wall.

Requirements of SP 5.13130.2009

In SP 5.13130.2009, paragraph 13.3.4, which sets out the requirements for the placement of detectors, was significantly revised and significantly increased in volume compared to previous versions, but it is difficult to say that this has added clarity. As in previous versions, all possible installation options are listed in a row: “if it is not possible to install detectors directly on the ceiling, they can be installed on cables, as well as walls, columns and other supporting building structures.” True, a new requirement appeared: “when installing point detectors on walls, they should be placed at a distance of at least 0.5 m from the corner”, which is well combined with European standards and with the general requirement introduced later in amendment No. 1 to SP 5.13130.2009 .

The range of distances from the ceiling of 0.1–0.3 m specified in NPB88-2001 for installing detectors on the wall was excluded, and now the distance from the ceiling when installing detectors on the wall is recommended to be determined in accordance with Appendix P, which contains a table with minimum and maximum distances from the ceiling to the measuring element of the detector, depending on the height of the room and the angle of inclination of the ceiling. Moreover, Appendix P is titled as "Distances from the top point of the overlap to the measuring element of the detector", on the basis of which it can be assumed that the recommendations of Appendix P relate to the placement of detectors in the case of inclined ceilings. For example, at a room height of up to 6 m and floor slope angles of up to 150, the distance from the ceiling (upper ceiling point) to the measuring element of the detector is determined in the range from 30 mm to 200 mm, and at a room height of 10 m to 12 m, respectively, from 150 up to 350 mm. At angles of inclination of the floor over 300, this distance is determined in the range from 300 mm to 500 mm for a room height of up to 6 m and in the range from 600 mm to 800 mm for a room height of 10 m to 12 m. Indeed, with inclined ceilings, the upper part of the room not ventilated, and, for example, in NFPA 72, in this case it is necessary to place smoke detectors in the upper part of the room, but only below 102 mm (Fig. 3).

Rice. 3. Placement of detectors at sloped ceiling according to NFPA 72

In the set of rules SP 5.13130.2009, information regarding the placement of detectors on the wall in a room with a horizontal ceiling in Appendix P, apparently, is missing. In addition, it can be noted that in the set of rules SP 5.13130.2009 there is a separate clause 13.3.5 with requirements for the placement of detectors in rooms with sloping ceilings: “In rooms with steep roofs, for example, diagonal, gable, four-slope, hipped, serrated, having a slope of more than 10 degrees, some of the detectors are installed in the vertical plane of the roof ridge or the highest part of the building. But in this paragraph, there is no reference to Appendix P and, accordingly, there is no prohibition on installing detectors literally “in the highest part of the building”, where their efficiency is much lower.

It should be noted that paragraph 13.3.4 refers to point fire detectors in general, i.e. both smoke detectors and heat detectors, and significant distances from the ceiling are allowed only for smoke detectors. Apparently, Appendix P is applicable only for smoke point detectors, this is indirectly indicated maximum height protected premises - 12 m.

Installation of smoke detectors on false ceilings

Paragraph 13.3.4 of the set of rules SP 5.13130.2009 states that "if it is impossible to install detectors directly on the floor, they can be installed on cables, as well as walls, columns and other supporting building structures." It is enough to refer the suspended ceiling to the load-bearing building structures, and in order to formally fulfill this requirement, the bases of point detectors are sometimes screwed onto the corners of the Amstrong tiles. However, point detectors, as a rule, are light in weight, they are not linear smoke detectors, which do not only have a significant mass and dimensions, but must also maintain their position throughout the entire period of operation in order to avoid false alarms.

The placement of detectors on a false ceiling is defined in the requirements of paragraph 13.3.15 of the set of rules SP 5.13130.2009, although initially it refers to a perforated suspended ceiling, but in the absence of perforation, at least two conditions given in this paragraph are not met:

- perforation has periodic structure and its area exceeds 40% of the surface;

- the minimum size of each perforation in any section is at least 10 m,

and as stated further: “If at least one of these requirements is not met, the detectors must be installed on a false ceiling in the main room. Right on the false ceiling.

Many manufacturers of smoke detectors produce mounting kits for inserting detectors into suspended ceiling which improves appearance premises (Fig. 4).

Rice. 4. Inserting the detector into a suspended ceiling using a mounting kit

In this case, the requirement given in clause 4.7.1.7 of GOST R 53325-2009 is usually fulfilled with a margin, according to which the design of the smoke detector "should ensure the location of the optical camera at a distance of at least 15 mm from the surface on which the IPDOT is mounted" (fire smoke detector optoelectronic point). It may also be noted that according to the British standard BS5839, fire detectors must be installed on the ceiling so that their sensing elements are located below the ceiling in the range from 25 mm to 600 mm for smoke detectors and from 25 mm to 150 mm for heat detectors. Accordingly, when inserting foreign smoke detectors into a suspended ceiling, mounting kits ensure that the flue is located 25 mm below the ceiling.

Contradictions in Change #1

When adjusting in clause 13.3.6 of the set of rules SP 5.13130.2009, a new and categorical requirement was introduced: “The horizontal and vertical distance from the detectors to nearby objects and devices, to electric lamps in any case should be at least 0.5 m” . Notice how the phrase "in any case" exacerbates this requirement. And one more general requirement: “The placement of fire detectors should be carried out in such a way that nearby objects and devices (pipes, air ducts, equipment, etc.) do not interfere with the effects of fire factors on the detectors, and sources of light radiation, electromagnetic interference do not affect the detector’s performance ".

On the other hand, by new version clause 13.3.8, "point smoke and heat fire detectors should be installed in each compartment of the ceiling with a width of 0.75 m or more, limited building structures(beams, girders, ribs of plates, etc.) protruding from the ceiling at a distance of more than 0.4 m. However, to fulfill the unconditional requirement of clause 13.3.6, the width of the compartment must be at least 1 m plus the size of the detector. With a compartment width of 0.75 m, the distance from the detector, even without taking into account its dimensions, “to nearby objects” is 0.75/2 = 0.375 m!

Another requirement of clause 13.3.8: “If building structures protrude from the ceiling at a distance of more than 0.4 m, and the compartments they form are less than 0.75 m wide, the area controlled by fire detectors indicated in tables 13.3 and 13.5 is reduced by 40%", also applies to floors with beams over 0.4 m in height, but the requirement of clause 13.3.6 does not allow installing detectors on floors. And the Appendix P already mentioned here from the set of rules SP 5.13130.2009 recommends the maximum distance from the upper overlap point to the measuring element of the detector 350 mm at overlap angles up to 150 and at a room height of 10 to 12 meters, which excludes the installation of detectors on the lower surface of the beams. Thus, the requirements introduced in clause 13.3.6 exclude the possibility of installing detectors under the conditions specified in clause 13.3.8. In some cases, this regulatory problem can be solved by using linear smoke or aspiration detectors.

There is one more problem with the introduction in clause 13.3.6 of the requirement "The distance from the detectors to nearby objects in any case must be at least 0.5 m." We are talking about the protection of the ceiling space. In addition to the mass of the cable, air ducts and fittings, the suspended ceiling itself is often located at a distance of less than 0.5 m from the ceiling - and in this case, how to satisfy the requirement of clause 13.3.6? Relate the false ceiling to 0.5 m plus the height of the detector? Absurd, but the exclusion of this requirement for the case of overhead space is not mentioned in clause 13.3.6.

British standard BS 5839 requirements

Similar requirements in the British standard BS 5839 are set out in more detail in a significantly larger number of paragraphs and with explanatory figures. Obviously, in the general case, objects near the detector have a different effect depending on their height.

Ceiling barriers and obstacles

First of all, a restriction is given on the placement of point detectors near structures considerable height located on the floor and significantly affecting the detection time of controlled factors, in a rough translation: “Heat and smoke detectors should not be installed within 500 mm of any walls, partitions or obstructions to the flow of smoke and hot gases, such as structural beams and ducts , in the case where the height of the obstacle is greater than 250 mm.

The following requirement applies to structures of lower height:

Rice. 5. The detector must be separated from the structure, the height of which is up to 250 mm, at least twice its height.

“Where beams, ducts, luminaires or other structures adjacent to the ceiling and obstructing the flow of smoke do not exceed 250 mm in height, detectors should not be installed closer to these structures than twice their height (see Figure 5)” . This requirement, which is absent in our standards, just takes into account the size of the "dead zone" depending on the height of the obstacle that the air flow has to go around. For example, with an obstacle height of 0.1 m, it is allowed to move the detector from it by 0.2 m, and not by 0.5 m, according to clause 13.3.6 of the code of rules SP 5.13130.2009.

The following requirement, also missing from our codes, concerns beams: "Ceiling obstacles, such as beams, exceeding 10% of the total height of the room must be considered as walls (Fig. 6)". Accordingly, abroad, in each compartment formed by such a beam, at least one detector must be installed, and our detectors, respectively, 1, or 2, or 3, or even 4 according to SP 5.13130.2009, but this is a topic for a separate article. However, it should be noted that the requirement of clause 13.3.8 “Point smoke and heat fire detectors should be installed in each compartment of the ceiling ...” leaves open the question, what is the minimum number of them in each compartment? Moreover, if we consider the 13th section of the set of rules of SP 5.13130.2009, then according to clause 13.3.2 “at least two fire detectors should be installed in each protected room, switched on according to the “or” logic circuit, and according to the 14th section for installation two detectors in the room, a number of conditions must be met, otherwise the number of detectors must be increased to 3 or 4.

Rice. 6. Beams exceeding 10% of the total height of the room should be considered as walls

Free space around the detector

And finally, we got to the analogue of our requirement, clause 13.3.6 of the set of rules SP 5.13130.2009, however, the common value with the requirement of the BS 5839 standard is practically only 0.5 m: “The detectors must be placed in such a way that free space within 500 mm below each detector (Fig. 7)." That is, this requirement specifies a space in the form of a hemisphere with a radius of 0.5 m, and not a cylinder, as in SP 5.13130.2009, and applies mainly to objects in the room, and not on the ceiling.

Ceiling space protection

And the following requirement, also missing in SP 5.13130.2009 with amendment 1, is the placement of detectors in the overhead space and under the raised floor: “In non-ventilated spaces, the sensitive element of fire detectors should be located in the upper 10% of the space or in the upper 125 mm, depending on which is greater” (see Fig. 8).

This requirement shows that this case should not be associated with the requirement of a free space of 0.5 m around the detector for rooms and excludes the possibility of "inventing" the detector to protect two spaces.

In the first part of the article, the arrangement of point fire detectors was considered in the simplest case, on a flat horizontal ceiling in the absence of any obstacles to the spread of combustion products from the source. In the second - the placement of point fire detectors, taking into account the influence of surrounding objects on the floor. The third part is devoted to more significant obstacles to the spread of smoke in the room: beams, racks, stacks, partitions, etc.

Critical airflow rate

For smoke detectors, the main characteristic is usually the sensitivity measured in the smoke duct in dB/m. However, in real conditions, the efficiency of detecting the source of a smoke detector in most cases depends on the so-called critical speed - the minimum speed of the air flow at which smoke begins to enter the detector's smoke chamber, overcoming aerodynamic resistance. That is, to detect a fire, it is necessary not only to have smoke of sufficient specific optical density at the location of the smoke detector, but also a sufficiently high air flow velocity in the direction of its smoke intake. The American fire alarm standard NFPA 72 for smoke detectors provides a calculation using the critical airflow rate method. It is believed that if the critical speed of movement of the smoke-gas-air mixture from the source was reached at the location of the smoke detector, then the concentration of smoke is sufficient to generate an alarm.

In the US UL standard for smoke detectors, the sensitivity of the smoke duct detector is measured at a minimum airflow velocity of 0.152 m/s. (30 ft/min.). In NPB 65-97, the minimum air flow velocity in the smoke duct, at which the sensitivity of the smoke detector was measured, was to be set equal to 0.2 ± 0.04 m/s, as in the European standard EN 54-7 for smoke point detectors. However, in the current GOST R 53325-2009 clause 4.7.3.1, this value was replaced by an air flow velocity range of 0.20÷0.30 m/s, and in the draft new edition of GOST R 53325, the same range is defined as : "set the airflow speed to (0.25 ± 0.05) m/s". Based on what experimental studies was this adjustment made, which determines the possibility of a significant decrease in the efficiency of domestic smoke detectors compared to European and American detectors? And some fire detectors with “high” protection against dust due to a decrease in the area of the chimney, with a critical speed of slightly less than 1 m / s, stop responding to smoke during real fires.

In a room with a flat horizontal ceiling, hot gas and smoke from the hearth rises due to convection, while it is diluted with clean and cold air, which is drawn into the upward flow. The American Fire Alarm Standard NFPA 72 Smoke Detector Determination Guide provides a model for the spread of smoke from a hearth to account for the effect of stratification. Smoke occupies the volume in the form of an inverted cone with an angle equal to 220, respectively, at a height H, the radius of the area filled with smoke is 0.2 N. When propagating along the ceiling, the smoke also mixes with clean, cold air, while its temperature decreases, it is lost lift and airflow speed becomes below critical. These physical processes determine the impossibility of detecting a source with a point smoke detector at significant distances and limiting the maximum distance to the detected source, and not the area, as in our standards.

Rice. 1. Free divergence of smoke from the hearth

Compartments of the premises, dedicated parts of the premises, protected zones

The set of rules SP 5.13130.2009 clause 13.3.9 contains the requirement: “Point and linear, smoke and heat fire detectors, as well as aspiration ones, should be installed in each compartment of the room formed by stacks of materials, racks, equipment and building structures, the upper edges of which separated from the ceiling by 0.6 m or less. As already noted, this requirement is not new, but there is no clarity regarding the minimum number of detectors in each compartment. It is clear that if the room is divided into compartments, then the smoke accumulates in the same compartment with the fire, and, as in separate rooms, it is necessary to install at least 2 detectors with the logic of generating an “or” signal, or at least 3-4 detectors when generating signals when not triggered. less than two fire detectors connected according to the logical "and" scheme. Moreover, it is obvious that if in 3 compartments of the room one detector is installed in a two-threshold loop, then the system will be inoperative even if all the detectors and the device are in full working order. However, what justification can be found in the requirements of the set of rules SP 5.13130.2009 for installing more than one detector in a compartment, if the requirements for distances are provided. After all, design is usually carried out on the basis of a minimum cost for equipment, and rarely anyone thinks about the efficiency and working capacity.

According to clause 13.3.2, in the room, as well as 30 years ago, it is required to install at least two fire detectors, switched on according to the “or” logic scheme without any reservations, although in clause 13.3.3 the assumption of installing one detector is given not only in the protected premises, but also in "dedicated parts of the premises". Clause 14.2 also states that at least two detectors according to the logical scheme “or” are installed “in the room (parts of the room)” with placement at standard distances. And in clause 14.3, already “in the protected room or protected zone" there must be at least 2-4 detectors. And in the 3rd section of clause 3.33 there is the term "fire alarm control zone (fire detectors)", which is defined as "a set of areas, volumes of the premises of the facility, the appearance in which fire factors will be detected by fire detectors."

The variety of terms used in the set of rules SP 5.13130.2009 without defining them significantly complicates the fulfillment of the requirements set forth in them in this way. Excessive equipment savings can only be limited by the general requirement given in clause 14.1: “The formation of signals for automatic control of warning, smoke removal installations or engineering equipment of the facility should be carried out in a time not exceeding the difference between the minimum value of the time for blocking escape routes and the evacuation time after the fire alert. And when one detector is installed in 3 compartments of the room, the formation of a “fire” signal will occur only when the fire zone covers several compartments. If 2 detectors are installed in each compartment, then, provided that both detectors are operational, a “fire” signal will be generated adequately, but if one of them fails, the requirement will not be met. Inconsistencies in requirements and confusion with terms could be avoided if it were defined, as in the British standard BS 5839, that when the room to be protected is divided by partitions or shelving, the top edge of which is located within 300 mm from the ceiling, (rather than 600 mm, as in SP 5.13130.2009), they should be considered as solid walls that rise to the ceiling (Fig. 2). If such a definition were present in SP 5.13130.2009, then there would be certainty when determining the number of detectors depending on their type.

Rice. 2. Partitions are treated like walls to ceiling

Floors with beams

The British standard BS 5839 contains requirements for the placement of fire detectors in several paragraphs. According to the type of beam, it can be divided into at least 3 classes: single linear beams, frequent linear beams (Fig. 3) and beams forming cells like honeycombs. For each type of beam, the corresponding requirements for the installation of detectors are given.

Rice. 3. Combination of shallow and deep beams

In amendment No. 1 to the set of rules of SP 5.13130.2009 in clause 13.3.8, they returned to the wording from NPB 88-2001 clause 12.20, which is based on the requirements of SNiP 2.04.09-84 clause 4.4: “Smoke and heat fire detectors should be installed in each compartment of the ceiling, limited by building structures (beams, girders, plate ribs, etc.) protruding from the ceiling by 0.4 m or more. And here, similarly to compartments formed by stacks, it is necessary to formulate a requirement for how many detectors of each type should be installed in each compartment and how. Due to the uncertainty of the requirements, one detector is often installed in each part of the room, divided by a tall beam (Fig. 4).

Rice. 4. There is one detector in each compartment, at least 2 in the room.