A powerful biofield in humans can be easily identified by the following features: Lack of ...

If you need to get durable and reliable fence, which is enough for a lifetime, then they are most often used as support pillars metal pipes for fences. Their installation is much cheaper than the construction of reinforced concrete and stone pillars, and their durability with correct installation almost the same.

After construction, no matter what kind of cladding you use for the fence, you can be completely sure that it will not collapse after 5 years, unlike wood, which will quickly rot.

Concrete pipes can be sheathed with the following materials:

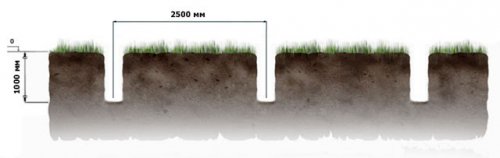

For example, if the perimeter of your site is 150 meters, and the spans are 2.5 meters, then the calculation will be as follows:

150 / 2.5 = 60 + 3 = 63 pillars.

For those who want to save money on installing a fence, it is worth mentioning about the fence posts from plastic pipes and asbestos pipes. Of course, they are not as strong as metal ones, but they are much lighter and cheaper.

If you want to install temporary fence in the country, then they are perfect for attaching light sheathing ( plastic panels, chain-link mesh, wood). For example, the price of an asbestos pipe with a diameter of 100 mm and a length of 3.95 m is only 300-400 rubles.

First, we drive in the pegs in the corners of the site and the wicket and pull the cord over them. Along it with the same pitch we drive in pegs for intermediate pillars. At the border of neighboring areas, it is better to retreat 5 cm so that later there will be no misunderstandings.

After finishing the marking, first of all, we dig holes in the corners and put up pillars. If the soil is soft, this can be done with a regular shovel, but it will be faster to drill them with a hand drill.

In order for the pipes to be more stable, you need not only to dig them into the ground, but to fill them with concrete. To do this, after dug a hole, you need to pour a 10 cm layer of sand on the bottom, fill it with water and tamp it well.

Then the pillar is checked on each side with a level and is set exactly vertically. To prevent it from falling, we put wooden supports on all sides.

We pull a cord between the extreme pillars along the top, it will help to expose intermediate pillars in space and even in height. If some holes are deeper, we just add sand to the bottom.

Fence welding

After a few days, you can start fixing horizontal lags. They are usually attached for welding. In some cases, you can attach an additional stiffener at a diagonal or center. After welding, the posts and cross pipes must be painted.

Thus, the frame is completely ready, now it can be sheathed with any chosen material. All that remains is to install a wicket and gates for cars, which can be made with your own hands from pipes of the same diameter. To do this, you need to weld the door frame and sheathe it. Then you need to weld the hinges and hang the door on the post.

Each person can make a fence made of metal pipes, but this will require welding and experience. But even without welding machine for joining pipes, you can use a mechanical fastener. That is why this a good option for summer cottages, where you need an inexpensive, but fast and reliable property protection.

When building a fence for a private house or summer cottage, you cannot do without supporting pillars. Poles can be made of brick or stone, but these materials are quite expensive and not everyone can afford to buy them, especially if the fence is long. But there is a good alternative to these materials - this is a pipe. It is strong enough, reliable, will last a long service life, but only if all technological process... But how to install fence posts from pipes so that they become reliable support?

Recently, more and more often, residents of private estates are opting for metal profile fences, and in order to build them, they cannot do without pipes as supports. For a metal profile, two types of pipes are best supplied:

As can be seen from the above, you can save money if you choose the right pipes; moreover, in this way you can facilitate the installation of the profile sheet. For supports, they buy an overall pipe, and for transverse lags, a thin-walled one.

So, in order to build a fence with a height of more than two meters, experts advise stopping the choice on a pipe with a diameter of 80 mm, and if the fence is 2 meters or lower, then a 60 mm pipe will be enough.

Due to the fact that round pipes are much more expensive, they are rarely used. They mainly use a profile type with the following dimensions:

It is only possible to calculate the number of supports for the fence if the perimeter of the fence is completely measured. The footage must be divided by a step - this is the distance between the posts and as a result we get required number. Professional craftsmen it is advised to install supports in increments of 2 meters. The length of the support must be taken 30% more than the planned height of the hedge, because that is how much will need to be lowered into the ground.

To connect the posts use shaped tube, which is pre-cut in half, because in this way it is easier to fix it to a round support. To do this, you need to purchase a 20x40 mm pipe. For a fence 2 meters high, two crossbars are enough, but if it is higher, then three. This is due to the fact that at strong wind the profile sheet can bend.

Pipes fixed in the ground with concrete mix can be sheathed with different materials:

But it is imperative to remember that metal pipes as supports will last longer if they are immediately covered with an anti-corrosion compound and subsequently covered with paint from time to time. Before answering the question of how to install pipes for the fence, you need to know what standards exist, because certain parameters must be observed: distance from the road, building, gas pipe.

Erecting a fence is half the battle, you need to correctly calculate its location so that you do not have to demolish it in the future. Today, there are special regulations in the country that must be observed. There is SNiP - a document where all norms and distances from buildings are spelled out.

From land plot neighbors, the fence should be:

In addition, the height of the fence should not exceed 1.8 meters, it is also very important that the fence is transparent, although this issue can be agreed with the neighbors and if they give written permission, then any type of fence can be erected. You also need to remember that the distance from the underground gas pipe must be at least 1 meter. The pipeline and chimney are also taken into account during the construction of the fence, all these standards are spelled out in the relevant documents, and you can get them from local authorities. So, when all the questions about installing a fence for a private house are agreed, you can start marking the territory and digging holes for the support pillars.

Today, there are several methods of mounting supports, which serve as pipes:

Which of these methods to choose is decided by the owner of the site, because each of them has its own characteristics, and we will try to tell you about them.

This type of installation of supports for the construction of the fence is the most economical. Conduct assembly work necessary with an assistant. When carrying out such work, the guide element is located directly in the pipe itself. The verticality of the support is checked several times in order to ultimately know for sure that the support is perfectly level. But it is worth remembering that this method cannot be used for areas with stone or gravel soil.

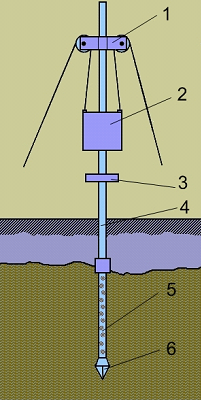

Screw piles

In our modern times there are many unique technologies, one of them is the installation of pipes for the fence in the form screw piles which are considered ideal option for residents of areas with complex and heaving soils. They can be easily installed to any depth and you can be sure that they are reliable and will last a long time. You can check their correct and even installation using laser level, and if there is no such thing, then great normal will do plumb line.

This type of installation is perfect for light types of fences, for example, chain-link mesh or timber. When installing pipes for the fence in this way, it is necessary to dig holes around the entire perimeter of the future fence. After that, a support is installed in them, its verticality is checked by the level and sprinkled with the same soil, while tamping it well.

Advice: For sandy soil, it is better to use a crushed stone pillow to secure the support more securely.

As a rule, most often the choice falls on this method of mounting support pillars made of metal and all due to the fact that it is simple and quite strong and reliable.

The work begins with the fact that they dig holes around the entire perimeter of the yard, their depth should be about a meter. After that, a cement-based solution is prepared: 1 part of cement 3 - crushed stone and 3 sand. Add water gradually in order to end up with a solution that can be put in, not poured. The solution is prepared only after everything is ready for laying it, otherwise it will harden and be unusable. In each hole, a pipe should be installed perfectly evenly, and then concrete is poured. After pouring, the pipe is lifted slightly upward and held so that the solution grabs, as a result, the pipe will be fixed at the required height. This method will protect the support from rust, because it will not come into contact with the ground. The hole is poured to ground level, tamped well so that the air comes out, and left to freeze for a week. Only after that you can proceed to the construction of sections between them.

A fence installed in this way will last for many years and will not require special care from the owner.