INSTRUCTIONS AND PROPHECIES OF THE Blessed MOTHER ALIPIA GOLOSEEVSKY, Kyiv...

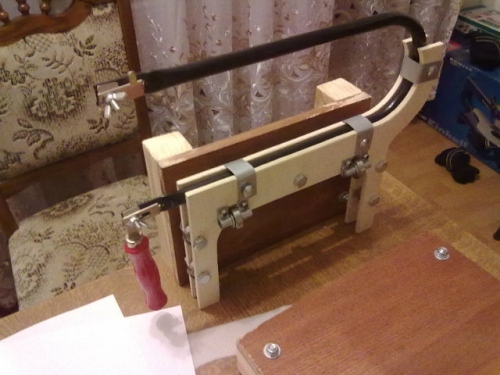

What if you need to use a jigsaw, but there is no desire to purchase it? Experienced craftsmen will answer that in this case the easiest way is to make a jigsaw with your own hands.

There are multiple ways to make and repair such a tool yourself. Below is a list of options for using the most simple and affordable of them.

Before you make a jigsaw, you should prepare inexpensive and affordable materials. Let's put them in the form of a list:

As a base for a manual jigsaw, you must use a bracket, which is made from a sheet of plywood (12 mm).

After that, a thickening should be made on the handle using a thinner plywood sheet (5 mm). Such a thickening is glued evenly on both sides of the handle, which, during subsequent work with a jigsaw, ensures its comfortable position in the hand. At the same time, the bracket and handle must be carefully processed with sandpaper and files of different classes.

The steel plate must be cut down with a chisel and the clamping jaws must be cleaned using a file. Next, you need a drill to make cuts in the jaws. Having taken this step, we proceed to cutting notches on them with a sharp chisel. Modify the left clamping jaw in such a way that a threaded hole for the bolt is made. We attach the jaws to the bracket, and then screw the bolts on the left clamp, securely fastening with a nut.

Desktop fixtures of this kind can be made both from scratch and through improvements to existing devices.

To make a new desktop mechanical jigsaw, you must first acquire the following tools and supplies:

First, we prepare the frame; an duralumin pipe is well suited for this purpose. During the manufacture of the frame frame, a passage must be provided through which an electrical wire is laid, which will provide the tool with power. Using a copper sheet, a U-shaped frame is made, which is then attached directly to the frame. In the area where the frame is connected to the handle of the jigsaw, the frame is screwed with screws.

Then we take a plastic base for drilling holes and mounting slots in it. On the prepared basis, we fix the jigsaw in such a way that the file can pass freely in the hole made. With clamps, we attach the finished fixture to a flat surface, for example, on a table.

For the manufacture of a jigsaw, you can use a sewing machine, the repair of which is not necessary. To make such a tool, you will need the following materials and tools:

We unscrew all the bolt fasteners from the lower parts of the machine structure, the entire working system with the thread is completely removed. We remove the metal mounting rod by knocking out and remove the drive shaft. We unscrew 2 more bolts and disassemble the panel that closes the sewing machine, its removal is quite simple. Gently remove the sewing needle and get to work.

First of all, we perform work with a slot for the needle. We expand it to such a size that a file can fit there. A needle file will help to cope with this task. It should be selected based on the size of the hacksaw blade. Try to make the size of the cut for the file as accurate as possible. Having bored the connector, you can install the canvas in place of the former needle holder. And in the end, turning the wheel, you need to check a few points in order to:

Such jigsaws are suitable for use in working with plywood, balsa wood and plastic, and when using an electric machine, such a device can be converted into an electric jigsaw.

In the event that the use of a manual jigsaw does not correspond to the tasks, and it is not possible to repair the electric ones, then it is worth using the options below that will allow you to make an electric jigsaw. Table type electric jigsaw:

We make markings for the slots in the plywood and carefully cut them out. If there is a pendulum stroke, it must be turned off. Then we place a hacksaw blade in the slot and attach it there. We also make several slots on plywood, drilling holes with a drill and connecting them to each other. Screws are placed in the slots made. As a result, it will not be difficult to fix the tool with clamps on flat surfaces. The device is ready.

Jigsaw from an electric drill:

Using sheet steel (4 mm) we make a product in the form of a C-shaped frame, which will be the base of the jigsaw. Next, attach it to the electric drill. For this purpose, it is necessary to create a special clamp made of steel sheet (1.5 mm), which will provide fastening. At the edges of the base we fix the spring slats. We will need a steel sheet (1 mm) to make clamps through which the saw will be attached. These clips on the edges will also help to strengthen the C-frame. And from a steel bar you can make a crank that will power the saw. For the connecting rod, we need a steel strip, which will allow us to create a crank mechanism.

On this, work on the manufacture of a jigsaw can be considered completed. Due to its massiveness, for safety reasons, it is better to clamp the drill in a vise during operation. And working materials are best placed on flat surfaces.

The jigsaw has long ceased to be a rarity and is present in the tool kit of almost any home craftsman. It is convenient, able to cut various materials, relatively safe. The electric jigsaw is designed for cutting curvilinear figures, closed or with a complex configuration. It is indispensable when performing many works on home improvement, in the construction of plasterboard structures, boxes, and other works.

However, in some cases it becomes difficult or inconvenient to work with a hand tool: poor visibility of the cut line interferes, it becomes necessary to hold the workpiece with both hands, etc. But the main problem with a manual jigsaw is that the saw blade moves to the side, which is especially evident when cutting materials of great thickness and with small radii of curvature. In such cases, you need a jigsaw machine, which you can create with your own hands.

The jigsaw machine is designed to perform a curved or straight cut of sheet materials along a predetermined contour or along guides.

Unlike a hand tool, where the file is fixed only at one end and holds its shape solely due to its own elasticity, on jigsaw machines the file is attached at both ends.

Such a machine can become a woodworking, desktop, saw, 4 in 1, made from a circular, drill and cutter, etc.

The main structural elements are:

The electric jigsaw successfully replaces the crank mechanism, setting in motion the frame with the file. There are simpler designs, where the jigsaw is simply attached upside down to the desktop from below, and the file either holds its position during operation due to its own elasticity, or is fixed on top with guides or a spring-loaded bracket that moves with it during operation. This allows you to reduce power losses when transmitting movement to the frame, but requires the use of elongated files, which are not often found on sale.

The main advantage of a jigsaw machine is the ability to perform an accurate cut, the absence of saw blade withdrawal to the side. In addition, the advantages of jigsaw machines over hand tools are:

Together with these advantages, one more thing appears - the need to organize a workplace for sawing disappears, since the machine has an appropriate plane for this.

Important! Along with the advantages, there are also obvious disadvantages - cutting out internal parts is much more difficult or impossible, only trimming along the outer contour.

There are ready-made platforms that allow you to quickly convert a hand tool into a machine tool. However, they are designed for jigsaws from a specific manufacturer and are not suitable for any device. In addition, the price of such platforms often far exceeds the cost of the instrument itself. Therefore, it is much easier to make a machine yourself.

Figure 2 - The design of the jigsaw machine

Figure 2 - The design of the jigsaw machine The basis is the desktop.

It has been empirically established that sheet metal tables demonstrate the greatest efficiency - they are durable, ensure mounting accuracy, do not require frequent replacement and do not reduce the working length of the file.

The jigsaw is attached to the table through the holes in the support plane, if necessary, it can be easily detached and used in the usual way.

The desktop is installed on the bed. It can be made of wood, chipboard or other materials. The main requirement is strength, easy access to the jigsaw and a size (height) convenient for the master.

At the end of the table, a rocker is installed, on which the second end of the file with a tensioner is attached. The simplest option is a conventional spring, which tensions the file and prevents it from drifting to the side with sudden changes in the cutting direction. The manufacture of this assembly is one of the most difficult stages of work, since the quality and cleanliness of sawing, as well as the magnitude of the load on the jigsaw mechanism and electric motor, depend on it.

There are two options for the design of the tensioner:

Both options have their pros and cons, the choice is usually made in favor of the option that is the simplest and most accessible in terms of technical capabilities.

Consider the procedure for the manufacture of a jigsaw machine. The design is a desktop with a jigsaw fixed from below. The rocker consists of a rigidly reinforced rack with a movable spring-loaded lever. This option is considered affordable and reliable, devoid of unnecessary components and parts.

For simplicity and clarity, it is recommended to sketch working drawings that will clarify some design features and answer questions about dimensions, connection points and other details of the assembly process.

The creation of the machine can be divided into three stages, which should be considered separately:

Before starting the direct manufacture of the machine, it is necessary to make some preparation. First of all, you should make a special adapter for installing the file. In most jigsaws, the landing end of the file is inserted into the socket and clamped with a screw.

The cutting body of the machine is a thinner and longer file with holes at the ends, which are put on special pins (or through which the fixing screws pass). Therefore, it is necessary to make an adapter, the lower part of which copies the shank of a standard saw blade for this jigsaw, and the upper part is equipped with a hole for a screw with a nut, with which the adapter is connected to a machine saw.

Here, the procedure is not limited by anything - some grind a part of the desired shape from a metal plate, others take a piece of a finished file with a shank and weld a steel washer to it, followed by processing for accuracy.

In addition, it is necessary to prepare the necessary tools and materials, including:

Figure 3 - Drawing of a jigsaw machine

Figure 3 - Drawing of a jigsaw machine This list is not exhaustive and additional tools or materials may be needed.

The first step is to make a desktop. A piece of plywood or chipboard of the planned size is sawn off. There are no special restrictions here, but you will have to take into account the size of the room in which the machine will be located. A table that is too small will be inconvenient for working with large details, and an excessive table area will take up a lot of space in the room (or workshop).

As a rule, when choosing the size of the table, they are guided by the size of the parts that will be processed on the machine. On the table, holes are made for attaching a jigsaw and a file. To do this, unscrew the sole from the tool, apply it to the table and mark the centers of the holes for the connecting bolts.

Important! The connecting bolts that fix the jigsaw on the work surface must be with a countersunk head so that they do not protrude from the plane of the table and do not scratch the workpiece during operation.

Figure 5 - Jigsaw rocker

Figure 5 - Jigsaw rocker The second step will be the manufacture of the rocker arm. It needs two elements:

For the rack, a profile pipe of rectangular section is taken and a support platform is welded in the lower part.

Its size should ensure the immobility, stability and reliability of the rack during operation under load.

The height should correspond to the length of the file in the maximum raised state, plus a small margin for the size of the attachment point.

The best option - in the middle position of the file, the movable lever is in a horizontal position.

The movable element is a beam mounted on a rack by means of a swivel joint. The length of the front part ensures that the attachment point of the file is located exactly above the corresponding element of the jigsaw. The back of the lever is connected to a spring that provides tension.

Then you need to make a tension unit. It is a conventional spring, which is tensioned with an adjusting screw. It is attached to one end of the spring, threaded into a special loop on the frame and pulled with a nut and washer.

Attention! From vibration, the tension nut is able to unwind, weakening the tension. It is recommended to fix it with a lock nut.

The assembly process is not difficult. You need to do the following:

If the calculations were done correctly, the file will move exactly vertically without yawing to the sides. It is recommended that before starting the jigsaw, check its progress and make sure that no unforeseen situations are expected.

When working with a jigsaw machine, you should adhere to the following rules:

In addition, you should remember the fire safety rules and always unplug the tool from the socket at the end of work.

Independent production of a jigsaw machine is not of fundamental difficulty, however, not every master has a need for it. As a rule, such devices are used by people who perform a large amount of work and need to create optimal conditions for this. Everyone chooses the design features of the machine for their own reasons and preferences, there are many options available. The quality and safety of the product directly depends on the degree of care and accuracy of assembly.

A desktop jigsaw is an indispensable thing for any owner who is used to doing housework on his own. Especially electric jigsaws are good for residents of the private sector, lovers of manual labor and summer holidays. From its prototype, an ordinary manual jigsaw, the desktop electric model has gone far enough. A desktop jigsaw makes it easier and faster to cut, not to mention improving quality.

The jigsaw is a saw, which is characterized by reciprocating movements of the saw blade, which acts as a working body. It has a ski designed to guide the saw blade when moving over the surface that is being processed, and making movements at a frequency of up to 3000 vibrations per minute.

This tool was invented in 1946. Its creator is Albert Kaufman, who replaced the needle in a sewing machine with a blade. The tool appeared on sale in 1947. The manual electric jigsaw has a body with a flat platform and a handle. The main difference between an electric jigsaw and a manual jigsaw is its greater functionality and cutting quality.

Inside is an electric motor and a special mechanism that drives the blade. In stationary jigsaws, there is no handle, and the platform is located on top. In front of the mechanism there is a guide, in the lower part there is a retractable blade that moves and makes cuts.

The tool works as follows: a table jigsaw file is securely fastened with clips in the slider. Reciprocating movements have a frequency of up to 3000 strokes and can be adjusted. The support platform allows the jigsaw to focus on the part being cut, so the work is carried out very accurately.

The jigsaw is an essential accessory for every workshop and every hobbyist. His thin file can successfully cut plywood, copper, iron, thick boards, brass, steel. Tools can be motorized, foot or hand-operated and are more productive. An electric jigsaw is simply indispensable for carpenters, woodworkers, furniture designers, drywall workers who make complex parts.

An electric jigsaw can perform straight and curved cuts on workpieces with complex shapes and various sheet materials without disturbing the external contour. Most often, desktop jigsaws are used for cutting wood and wooden plates, figures with a complex outline from laminate and drywall, plastic blanks, and also for cutting sheet metal.

Desktop electric jigsaw makes clean cuts of complex shapes and works with small

details. Due to the stable and fixed position during operation, high cutting accuracy is achieved. The file has a stable course thanks to the tension system and guides, which manual jigsaws lack. The large size of the table makes it stable, so that a precisely defined sawing direction is observed.

Today, a wide variety of electric jigsaws are presented on the power tool market, which differ in the nature of the application, technical characteristics, type of power supply and design features. In hardware stores you can buy a desktop jigsaw for every taste and budget.

By design features, it is difficult to classify, because each manufacturer seeks to provide its products with features that are designed to facilitate and improve the operation of the tool. In this regard, the shape of the handle is an important parameter.

Two types of handles have settled - mushroom-shaped and D-shaped. A jigsaw with a staple-like handle requires one-handed operation. This increases the possibility of using a jigsaw, but somewhat negatively affects the quality of the material cut.

Mushroom handles allow for more accurate cuts when holding the jigsaw with both hands, after fixing the workpiece to be cut. The choice of a jigsaw with a certain shape of the handle depends on the financial capabilities and personal preferences of the buyer. It is worth choosing the jigsaw with which it will be more convenient to work.

Household jigsaws are not intended for intensive use, but the low price of a desktop jigsaw and the power that is enough for domestic needs make them indispensable in the household.

Professional jigsaws are characterized by high wear resistance and the possibility of many hours of daily use (up to 8 hours). The significant power of such jigsaws allows you to process materials of great thickness. Extended equipment and improved features are reflected in the price.

Among professional jigsaws, industrial ones also stand out, which are characterized by greater adaptability to complex operations and drive features - for example, increased power supply voltage. Industrial models are machines that are designed for the woodworking industry.

By type of power supply, there are network and battery electric jigsaws. Network models are powered by a standard voltage power supply. If performance is important to you, then you should choose a corded power tool.

Cordless jigsaws provide independence from the presence of sockets and greater mobility during work. When buying a battery model, you should pay attention to the type of battery. Increased performance is inherent in lithium-ion batteries. Battery capacity is responsible for the duration of work without recharging.

The desktop electric jigsaw is a stationary design, so this type of cutting tool has many advantages. Modern models can work with wooden materials with a thickness of 40-50 millimeters. A narrow saw acts as a working body, which performs vertical reciprocating movements. Due to the peculiarities of the notching of the teeth and the mechanics of the movements of the file, the material is cut out by moving upwards.

The desktop electric jigsaw allows you to cut out complex decorative details, to make longitudinal, straight, oblique and transverse cuts. The wide tabletop allows you to process large parts and make cuts inside wide workpieces. Reliable fastening protects the body from unnecessary vibrations and allows you to well position the material, so the motor can work without overloading.

The advantages of desktop jigsaws include good accuracy and clarity of cuts, high safety and ease of use, wide customization options for the material and the required detail of the cut workpieces.

If you need to cut small parts, a manual jigsaw will not be very convenient. It is quite heavy, so you have to hold it with one hand and guide the workpiece with the other. And the desktop jigsaw is devoid of this drawback. Perhaps the inconveniences are too large sizes and the difficulty of working with large details.

The desktop jigsaw is a kind of mini-machine for cutting workpieces. If you buy a jigsaw in a store, most likely there will be an opportunity to select the power and adjust the frequency of the saw strokes. However, you can make the simplest homemade desktop jigsaw, and very quickly. You will need a manual jigsaw, a few screws, a small piece of plywood and just an hour of work.

A carefully made jigsaw will not be inferior to a factory-made one, and in some respects even surpasses it. It is not difficult to assemble such an electric jigsaw if you have the necessary materials. Next, we describe a simple scheme of such manipulations.

The design of the jigsaw includes the following components: a handle, a switch button, an insulating washer, a power cord, a frame, a heating thread, a screw clamp and an earring. First you need to make a frame. You will need a duralumin pipe with an outer diameter of up to twelve millimeters.

You can also use textolite with a thickness of at least ten millimeters or thick plywood for the base. But keep in mind, the lighter the frame, the more convenient the jigsaw will be to use. Be sure to provide a channel so that you can later lay the power cord. The best shape of the frame is the one with one of the sides deviated by 45 degrees.

Next, you need to make an earring. It is made of copper sheet with a thickness of one millimeter. After that, it is fastened with screws to the frame, where it connects to the handle. Thus, the screw, wing nut and earring will form a clamp in which the heating thread can be fixed. The thickness of the duralumin sheet should be up to 0.8 millimeters. It is necessary to make clamping cheeks from it, between which there is a button-switch.

After that, you need to cut a gap in the plywood through which the file can pass. It can be done with a drill. To do this, it is necessary to drill holes along the marking line, and smooth the transitions. Instead of plywood, you can use plastic, metal, plexiglass and others. Next, you place and drill mounting holes on the plywood and the base plate of the jigsaw.

Then you need to fix the jigsaw with screws on the plywood base so that the file can pass through the gap. You attach the structure to the table with a clamp so that the file is pointing up. You can also secure the platform in any way you can.

The jigsaw file remains conventional, but the possibilities for good sawing are expanded by freeing up the hands.

You can use a nichrome coil from any household heating device (for example, an iron) as a heating filament. It must be secured with tension between the ends of the frame bends. To heat up the thread, you need to apply a tension of about 14 V. To control the operating mode, you can use a rheostat.

The current is determined by the thickness and length of the nichrome filament. With the help of a rheostat, it will be possible to set the optimal current strength (no more than 3-5 A), which will affect the temperature to which the thread is heated. Before starting work, it is necessary to determine the current strength. But keep in mind that if the force is too high, the material being cut out can be caught in flames, and if it is not enough, it will not be taken. A do-it-yourself desktop jigsaw will allow you to cut out figures with complex contours from various types of materials.

When working with a desktop jigsaw, you must adhere to some rules:

If you have not yet fully understood how to make a desktop electric jigsaw, watch a video about this procedure. This tool allows you to cut complex parts from wood and other materials, to make longitudinal, oblique, straight and transverse cuts. With the help of an electric jigsaw, you can process large parts, wide workpieces and small products, which is not superfluous at home.

Cutting plywood with a hand jigsaw requires attention and time. The result is beautifully practical products.

A hand saw is used to process the material in order to create decorative elements. As a result of the processing of wood, plywood, plastic, handicrafts are created that have practical application and aesthetic value.

Figure sawing is an exciting hobby that brings practical, moral and material benefits. From plywood and wooden blanks you can make:

Beginners for carving can choose light drawings, simple diagrams, craft drawings, sketches that have a pleasant appearance. After mastering the sawing technique, you can try your hand at jewelry models with openwork fragments.

Using a jigsaw, you can make platbands for home design. A variety of sketches allows you to create this element, which will provide the decoration of the interior. By curly cutting, you can make crafts from wood.

You can cut out beautiful decor elements from plywood. Using stencils for a jigsaw, it is easy to make photo frames, mirrors and much more from blanks. Handmade will complement the design of the room, emphasize the chosen style.

To get a quality product and minimize the formation of defects, you need to work slowly, focus on the process. Before starting work, it is recommended to make sure that the thickness of the plywood is equal to the height of the groove on the printed sketch.

Schemes for sawing out with a tool can be of various sizes. To create a drawing of an interior item, such as a shelf, you will need to use A1 or A0 paper, and for toys you can use a standard sheet of cardboard.

The contour of the product is applied to the surface in compliance with the exact dimensions. Templates for sawing with a manual jigsaw can be found on special resources. But it’s easier to come up with your own compositions based on the type of workpiece. An individual approach to the development of a product scheme will emphasize the texture of the tree.

To qualitatively apply a contour to the surface of plywood or wood, print the template on thick paper. Transferring a drawing from an A4 drawing can be a lot of trouble if you draw an ornament with a pencil.

In order to apply contours, complex patterns, you can use auxiliary methods. One way involves the use of carbon paper. To do this, a carbon copy is placed on the workpiece. A template is placed on top and lines are drawn.

The drawing can be glued to plywood with 2-sided tape. When using glue, clean the surface with sandpaper. An affordable method involves the use of a stencil made using nail scissors. After preparation, the template is applied to the surface and each fragment is outlined with a pencil.

For convenience, the sheet is fixed with adhesive tape or insulating tape. The pattern can be applied thermally. For this, an inkjet printer is used, with which the diagram is printed. After that, the pattern is applied to the surface with the front side and processed with a heated iron.

Sawing out of plywood is carried out after drawing a drawing on the workpiece. Processing begins with the internal elements of the product, and then the outer contour is cut out. This order of work allows you to get a straight line, provides convenient fastening of the workpiece.

Holes for the canvas must be drilled in sharp places of the internal contour. This requires attention, as chips may form on the back. To avoid this, it is recommended not to make holes completely.

You can limit the depth with the help of an insulating tape that is wrapped around the drill. After that, turn the workpiece over and process the hole with an awl. After finishing work, the product is polished with a file or needle file.

Small items require delicate handling, so it is recommended to be smart when handling. To do this, cut off a thin strip of sandpaper and insert it into the jigsaw file instead of the canvas.

Sawing with a hand tool requires the equipment of a special machine with a clamp. This fixture is used as a base. During processing, the workpiece is fixed at chest level, which provides convenience and allows you to carefully monitor the process.

For beginners, it is important to be careful when using a jigsaw in order to work out smooth movements. Cutting blade for jigsaw fragile, so it is recommended to avoid distortions, sudden movements, overheating.

When machining a workpiece, the movements must be reciprocating, and the tool must be positioned vertically. The use of an electric jigsaw requires securing the workpiece to a workbench. With this equipment, workpieces with a thickness of 5 cm can be processed.

If the workpiece processing technology is violated, the tool may be displaced. The jigsaw may cut crookedly if the tool is tilted or mounted incorrectly. If the blade is stuck at the stage of forming curly elements, then you will need to carefully draw a new line parallel to the fragment with the defect.

The jigsaw for figured cutting is an arcuate frame. The tool is equipped with a handle, 2 mounts for the cutting blade, which allow you to cut patterns of varying complexity.

Depending on the type of work, different nozzles are selected. Thick saws are used for cutting contours, and thin canvases are used for openwork work. It is possible to mechanize the processing of workpieces with the help of an electric tool. To speed up the process, individual models are equipped with a pendulum mechanism.

A stationary electric tool that is mounted on a static surface resembles a sewing machine in principle. The use of equipment of this type eliminates the errors of a perpendicular cut.

Sawing with a jigsaw requires compliance with safety rules. The workplace must be properly equipped. When working, it is recommended to use personal protective equipment.

The idea of \u200b\u200bcreating a homemade jigsaw is most often due to the shortcomings that a factory hand tool has. You can make a small desktop machine with your own hands, which will include a pusher, a reciprocating motor, a file tension system. In this case, you do not need complex drawings - having understood the essence, it is easy to achieve a result.

The desire to create a homemade jigsaw may arise for several reasons:

Designing a jigsaw is not difficult. A typical structure looks like this:

The unit can be easily adapted to any torque source. A pair of pulleys (one is located on the motor shaft, the other drives the crank mechanism) allow you to vary the gear ratio, reducing the load on the power unit and allowing you to get the desired speed (they are also responsible for the number of saw strokes per minute) on the actuator.

The machine, built according to the above scheme, can have a very different configuration, the material of manufacture is also selected individually. An example of a finished installation looks like this:

A manual electric jigsaw is designed to form even cuts. At the same time, as the rollers, rod, and pusher wear out, the saw may be beating and deviate from a straight line, and the angle of attack may change. Regardless of the quality of the tool assemblies, the following features are always present:

It is even more difficult to work with thin saws designed for curly cuts. If there is no practice, it is very difficult to achieve a good result, especially on a thick slab or wood materials. Consider how you can make the work of a carpenter easier, and the result better.

A manual jigsaw machine is made on the basis of a simple table. This device is common, mass-produced, samples can be seen in the photographs below.

The mechanics of work is simple:

With the help of a table, jigsaws begin to cut in a straight line, but the possibilities of such a device are limited. If you remove the side stop and try to guide the workpiece, forming a curved cut, the same problems of saw deflection arise. The problem can be solved by using a simple saw, rigidly fixed with a pair of rollers. Making curly cuts is now convenient and fast. How homemade and industrial products of this type look like is shown in the following photos.

To perform very thin and precise curly cuts, you can make a machine from an electric jigsaw with a saw blade tension system. The idea of \u200b\u200bdoing it yourself is as follows:

As a tension block, a manual jigsaw clamp is used, to which an adapter is made, which, in turn, is inserted into the clamping device of the power tool rod. To ensure the adjustment of one freedom of movement, a pair of angles and a bolt are used. The result of the implementation of the idea is presented in the following photo.

The saw provides a clear vertical movement, you can create a good tension, but there is a mandatory runout in the horizontal direction. The canvas goes with pickup, it does not move in a straight line.

The development of this idea is in the next photo. Here the part fixing the trajectory moves, and the metal clamp provides structural rigidity and mechanical resistance.

The system is stabilized in two degrees of freedom, the cut made with its help is accurate and accurate. Using a diamond-coated cord for a hand jigsaw, you can cut glass without the formation of sloppy chips on the edges.

If you need to work extremely delicately and slowly, you will need to reduce the force on the cutting blade and at the same time provide a strong tension and precise movement of the file. To do this, a home-made jigsaw is equipped with spacers with long arms.

In this case, the power tool does not operate in the cut zone, but at some distance. This allows, depending on the wishes of the carpenter, to adjust the force, speed and amplitude of the saw movement. One of the options for implementing the idea is presented in the following photo.

Depending on the needs of the master, the structure can be made of steel, have additional fixing zones, the power tool can not be installed rigidly, but with the possibility of movement within its support beam.

In practice, such solutions are rarely used. For delicate work that is done constantly, it is much more profitable to purchase a specialized band saw that will ensure quality and productivity.

As can be seen from the presented designs, a jigsaw can even be made from a sewing machine with a moving stem.

technika.expert

A desktop jigsaw is an indispensable thing for any owner who is used to doing housework on his own. Especially electric jigsaws are good for residents of the private sector, lovers of manual labor and summer holidays. From its prototype, an ordinary manual jigsaw, the desktop electric model has gone far enough. A desktop jigsaw makes it easier and faster to cut, not to mention improving quality.

The jigsaw is a saw, which is characterized by reciprocating movements of the saw blade, which acts as a working body. It has a ski designed to guide the saw blade when moving over the surface that is being processed, and making movements at a frequency of up to 3000 vibrations per minute.

This tool was invented in 1946. Its creator is Albert Kaufman, who replaced the needle in a sewing machine with a blade. The tool appeared on sale in 1947. The manual electric jigsaw has a body with a flat platform and a handle. The main difference between an electric jigsaw and a manual jigsaw is its greater functionality and cutting quality.

Inside is an electric motor and a special mechanism that drives the blade. In stationary jigsaws, there is no handle, and the platform is located on top. In front of the mechanism there is a guide, in the lower part there is a retractable blade that moves and makes cuts.

The tool works as follows: a table jigsaw file is securely fastened with clips in the slider. Reciprocating movements have a frequency of up to 3000 strokes and can be adjusted. The support platform allows the jigsaw to focus on the part being cut, so the work is carried out very accurately.

The jigsaw is an essential accessory for every workshop and every hobbyist. His thin file can successfully cut plywood, copper, iron, thick boards, brass, steel. Tools can be motorized, foot or hand-operated and are more productive. An electric jigsaw is simply indispensable for carpenters, woodworkers, furniture designers, drywall workers who make complex parts.

An electric jigsaw can perform straight and curved cuts on workpieces with complex shapes and various sheet materials without disturbing the external contour. Most often, desktop jigsaws are used for cutting wood and wooden plates, figures with a complex outline from laminate and drywall, plastic blanks, and also for cutting sheet metal.

The desktop electric jigsaw makes clean cuts of complex shapes and works with fine details. Due to the stable and fixed position during operation, high cutting accuracy is achieved. The file has a stable course thanks to the tension system and guides, which manual jigsaws lack. The large size of the table makes it stable, so that a precisely defined sawing direction is observed.

Today, a wide variety of electric jigsaws are presented on the power tool market, which differ in the nature of the application, technical characteristics, type of power supply and design features. In hardware stores you can buy a desktop jigsaw for every taste and budget.

By design features, it is difficult to classify, because each manufacturer seeks to provide its products with features that are designed to facilitate and improve the operation of the tool. In this regard, the shape of the handle is an important parameter.

Two types of handles have settled - mushroom-shaped and D-shaped. A jigsaw with a staple-like handle requires one-handed operation. This increases the possibility of using a jigsaw, but somewhat negatively affects the quality of the material cut.

Mushroom handles allow for more accurate cuts when holding the jigsaw with both hands, after fixing the workpiece to be cut. The choice of a jigsaw with a certain shape of the handle depends on the financial capabilities and personal preferences of the buyer. It is worth choosing the jigsaw with which it will be more convenient to work.

Household jigsaws are not intended for intensive use, but the low price of a desktop jigsaw and the power that is enough for domestic needs make them indispensable in the household.

Professional jigsaws are characterized by high wear resistance and the possibility of many hours of daily use (up to 8 hours). The significant power of such jigsaws allows you to process materials of great thickness. Extended equipment and improved features are reflected in the price.

Among professional jigsaws, industrial ones also stand out, which are characterized by greater adaptability to complex operations and drive features - for example, increased power supply voltage. Industrial models are machines that are designed for the woodworking industry.

By type of power supply, there are network and battery electric jigsaws. Network models are powered by a standard voltage power supply. If performance is important to you, then you should choose a corded power tool.

Cordless jigsaws provide independence from the presence of sockets and greater mobility during work. When buying a battery model, you should pay attention to the type of battery. Increased performance is inherent in lithium-ion batteries. Battery capacity is responsible for the duration of work without recharging.

The desktop electric jigsaw is a stationary design, so this type of cutting tool has many advantages. Modern models can work with wooden materials with a thickness of 40-50 millimeters. A narrow saw acts as a working body, which performs vertical reciprocating movements. Due to the peculiarities of the notching of the teeth and the mechanics of the movements of the file, the material is cut out by moving upwards.

The desktop electric jigsaw allows you to cut out complex decorative details, to make longitudinal, straight, oblique and transverse cuts. The wide tabletop allows you to process large parts and make cuts inside wide workpieces. Reliable fastening protects the body from unnecessary vibrations and allows you to well position the material, so the motor can work without overloading.

The advantages of desktop jigsaws include good accuracy and clarity of cuts, high safety and ease of use, wide customization options for the material and the required detail of the cut workpieces.

If you need to cut small parts, a manual jigsaw will not be very convenient. It is quite heavy, so you have to hold it with one hand and guide the workpiece with the other. And the desktop jigsaw is devoid of this drawback. Perhaps the inconveniences are too large sizes and the difficulty of working with large details.

The desktop jigsaw is a kind of mini-machine for cutting workpieces. If you buy a jigsaw in a store, most likely there will be an opportunity to select the power and adjust the frequency of the saw strokes. However, you can make the simplest homemade desktop jigsaw, and very quickly. You will need a manual jigsaw, a few screws, a small piece of plywood and just an hour of work.

A carefully made jigsaw will not be inferior to a factory-made one, and in some respects even surpasses it. It is not difficult to assemble such an electric jigsaw if you have the necessary materials. Next, we describe a simple scheme of such manipulations.

The design of the jigsaw includes the following components: a handle, a switch button, an insulating washer, a power cord, a frame, a heating thread, a screw clamp and an earring. First you need to make a frame. You will need a duralumin pipe with an outer diameter of up to twelve millimeters.

You can also use textolite with a thickness of at least ten millimeters or thick plywood for the base. But keep in mind, the lighter the frame, the more convenient the jigsaw will be to use. Be sure to provide a channel so that you can later lay the power cord. The best shape of the frame is the one with one of the sides deviated by 45 degrees.

Next, you need to make an earring. It is made of copper sheet with a thickness of one millimeter. After that, it is fastened with screws to the frame, where it connects to the handle. Thus, the screw, wing nut and earring will form a clamp in which the heating thread can be fixed. The thickness of the duralumin sheet should be up to 0.8 millimeters. It is necessary to make clamping cheeks from it, between which there is a button-switch.

After that, you need to cut a gap in the plywood through which the file can pass. It can be done with a drill. To do this, it is necessary to drill holes along the marking line, and smooth the transitions. Instead of plywood, you can use plastic, metal, plexiglass and others. Next, you place and drill mounting holes on the plywood and the base plate of the jigsaw.

Then you need to fix the jigsaw with screws on the plywood base so that the file can pass through the gap. You attach the structure to the table with a clamp so that the file is pointing up. You can also secure the platform in any way you can. The jigsaw file remains conventional, but the possibilities for good sawing are expanded by freeing up the hands.

You can use a nichrome coil from any household heating device (for example, an iron) as a heating filament. It must be secured with tension between the ends of the frame bends. To heat up the thread, you need to apply a tension of about 14 V. To control the operating mode, you can use a rheostat.

The current is determined by the thickness and length of the nichrome filament. With the help of a rheostat, it will be possible to set the optimal current strength (no more than 3-5 A), which will affect the temperature to which the thread is heated. Before starting work, it is necessary to determine the current strength. But keep in mind that if the force is too high, the material being cut out can be caught in flames, and if it is not enough, it will not be taken. A do-it-yourself desktop jigsaw will allow you to cut out figures with complex contours from various types of materials.

When working with a desktop jigsaw, you must adhere to some rules:

If you have not yet fully understood how to make a desktop electric jigsaw, watch a video about this procedure. This tool allows you to cut complex parts from wood and other materials, to make longitudinal, oblique, straight and transverse cuts. With the help of an electric jigsaw, you can process large parts, wide workpieces and small products, which is not superfluous at home.

strport.ru

For slotted carving and cutting out small parts from wood, plywood, plexiglass, plastics and other materials, jigsaws of various designs and types are used. It can be manual ("pioneer"), mechanical and electric jigsaws. Various magazines cited diagrams of home-made jigsaws driven by electric motors and even electric drills. But with the advent of the sale of manual electric jigsaws, it became possible to both install them on a table for sawing large parts, and use them as a drive for jigsaws for cutting small parts. The manual jigsaw is well balanced, powerful enough and has a speed control, which greatly expands the possibilities of its application.

Still, in my opinion, the electric jigsaw has a significant drawback, this is the inability to adjust the amplitude of the stroke of the nail file. But I dealt with this shortcoming by making a file stroke regulator.

The basis for the manufacture of the machine was taken from the version printed in Wood magazine No. 12 1986.

The dimensions of the rocker arms were chosen based on their own needs. It should be borne in mind that by increasing the length, we will increase the size of the workpiece, this is a plus. But at the same time, we will increase the vibration of the file, as well as the mass of the rocker arms, which will lead to an increase in the vibration of the entire machine, and this is a minus. Therefore, we make the length no more than necessary. An increase in the rear of the rocker arms will lead to easier file tension, but again, to an increase in mass and, accordingly, vibration. There is an opinion that by balancing the rocker relative to the swing axis, it is possible to reduce the vibration of the machine. In my opinion, this is not correct.

Vibration can be reduced by reducing the mass of the rocker arm as much as possible. But at the same time it is necessary that it remains rigid, and can withstand heavy loads.

For tensioning, it is convenient to use eccentric clamps from a bicycle. The tension of the nail file should be implemented through a rigid spring. It will help reduce the number of nail file breaks.

The nail file fastening should quickly and reliably fix nail files of different sizes.

The slats on which the rocker arms are attached must be securely connected to each other in order to reduce vibration.

The entire structure of the machine must be rigid and reliable. Management should be in a convenient location.

I will answer all your questions.

I wish you successful crafts.

shenrok.blogspot.ru

instrument.guru > DIY > using drawings

With the help of a homemade jigsaw, anyone can make furniture, modern comfortable shelves and other wood products. Its mechanism helps to cut wooden parts of absolutely any shape. And also with its help it is possible to process plastic and other dense materials. In order for the jigsaw to comply with all norms and rules, you need to carefully approach the choice of its design. Additionally, drawings from the network will help to make a jigsaw machine with your own hands.

Absolutely any electric homemade jigsaw contains the following parts:

The material to be processed should be laid on the work surface. Many models are equipped with a rotary mechanism that changes the inclination of the cutting surface. In order to facilitate the application of markings on the processed material, graduation is applied to the working surface. It is worth choosing a jigsaw with a large desktop size, because it will make the longest cut. Basically, for most models of electric jigsaws, this indicator is about 35 centimeters. The optimal drive power for a do-it-yourself jigsaw machine is no more than 200 watts.

The crank assembly mechanism is able to convert the rotation of the drive into translational motion and transmits it to the saw. The optimal frequency of the saw movement per minute is about 900, and the amplitude of the vertical movement should not exceed 6 centimeters.

Many types of electric jigsaws are equipped with a speed controller, which allows you to adjust depending on the type of material. A jigsaw file is capable of processing wood and plastic up to 12 centimeters thick, with a length of up to 40 centimeters. To work with different materials, the files can be changed, their width ranges from 2 to 12 millimeters. The manual tension mechanism secures the blade for a smooth cut. Its role is performed by spring or helical springs.

All electric jigsaw machines are usually divided according to the following criteria:

The most popular are electric jigsaws with a lower support, in which the bed is divided into upper and lower parts. The first contains the cleaning and cutting modules, and the second contains the electric motor, controller module, switching and transmission mechanisms. These machines can process absolutely any sheets of material.

Double caliper jigsaws have a major difference. It lies in the fact that in the upper part of the bed there is another rail. Such equipment is well suited for the manufacture of oversized products. Such devices are very easy to install and allow you to process products with a thickness of not more than 9 centimeters. Additionally, the machine comes with a convenient desktop with adjustable height and angles.

Suspended jigsaws are not equipped with a stationary frame and have great mobility. When performing work, the cutting module moves, not the material being processed. The working module itself is fixed on the ceiling on its own, which is why the size of the workpiece does not matter. The cutting mechanism moves with its own hands, regardless of the bed. In this case, it becomes possible to make a wide variety of patterns.

Electric jigsaws with stops and a degree scale are ideal for the most precise work with the help of drawings. Their design helps to avoid errors during operation. Universal type jigsaws are capable of doing several types of work. This is, first of all, cutting, grinding, polishing, drilling and many others.

When developing a drawing for a homemade jigsaw machine, the total number of elements must be reduced to a minimum. A saw with a fixed rocking chair, an electric motor and a bed is enough. If desired, a motor from any electric machine is suitable. Much more fortunate are people who own a manual jigsaw. It is necessary to make a special stand from a plywood sheet and fix a jigsaw on it. To fix it, it is worth making holes in the base of the jigsaw. Thus, the simplest jigsaw machine can be considered ready.

When developing a drawing for a homemade jigsaw machine, the total number of elements must be reduced to a minimum. A saw with a fixed rocking chair, an electric motor and a bed is enough. If desired, a motor from any electric machine is suitable. Much more fortunate are people who own a manual jigsaw. It is necessary to make a special stand from a plywood sheet and fix a jigsaw on it. To fix it, it is worth making holes in the base of the jigsaw. Thus, the simplest jigsaw machine can be considered ready.

Next, it’s worth talking about more functional and complex models of devices that you can do yourself. A home-made frame is made from a sheet of plywood 12 millimeters thick, textolite or plastic. Such a bed is a working surface, the base of the machine and a special box for the location of various mechanisms and an electric motor.

On the reverse side, it is necessary to place an eccentric with a rocking chair, which must be connected with a metal plate with bearings and bushings. This whole structure must be fixed with screws. To install the intermediate shaft, you need to find several bearings. A special metal pulley fits quite tightly onto the shaft, and the screw connector is securely fastened. Similarly, you need to make a homemade eccentric for the device.

In order to change the frequency of movement of the rocking chair, it is necessary to make several through holes on the installed flange and cut threads into them. They must be removed from the central axis at different distances. By changing the place where the screw is screwed in, it is possible to adjust the amplitude of movement of the rocking chair, which consists of several wooden yokes attached to the rack with hinges. The ends of the rocker arms have through cuts into which tension screws are inserted. A file is attached to the other ends, moving with the help of metal hinges. For fixing, the file is installed in a special groove of the working surface.

The saw blade attachment can be considered the most important. When assembling a jigsaw machine with your own hands, this part should be given great attention. The plates inserted into the rocker arms carry a huge load during operation, which is why they need to be strengthened and tightened with fasteners with high quality. The two tie-down earrings do not need to be tightly compressed with screws, which will allow the axle hinges to move.

The saw blade attachment can be considered the most important. When assembling a jigsaw machine with your own hands, this part should be given great attention. The plates inserted into the rocker arms carry a huge load during operation, which is why they need to be strengthened and tightened with fasteners with high quality. The two tie-down earrings do not need to be tightly compressed with screws, which will allow the axle hinges to move.

The rocker arm mechanism is best made from solid material. On one side, you need to make a groove for the rocker, and on the other, you need to cut a rectangular opening for the second rocker. In order to make it easier to make holes, it is worth folding the rack from several parts.